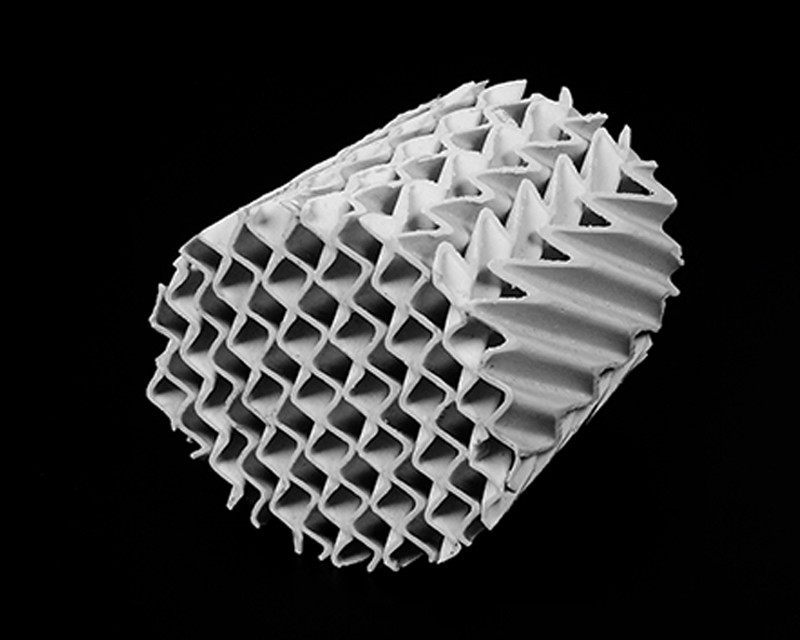

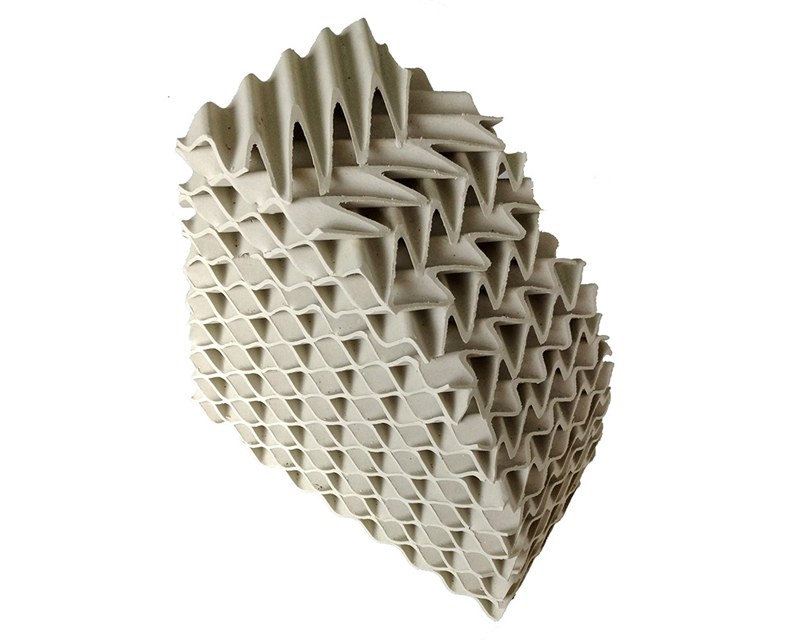

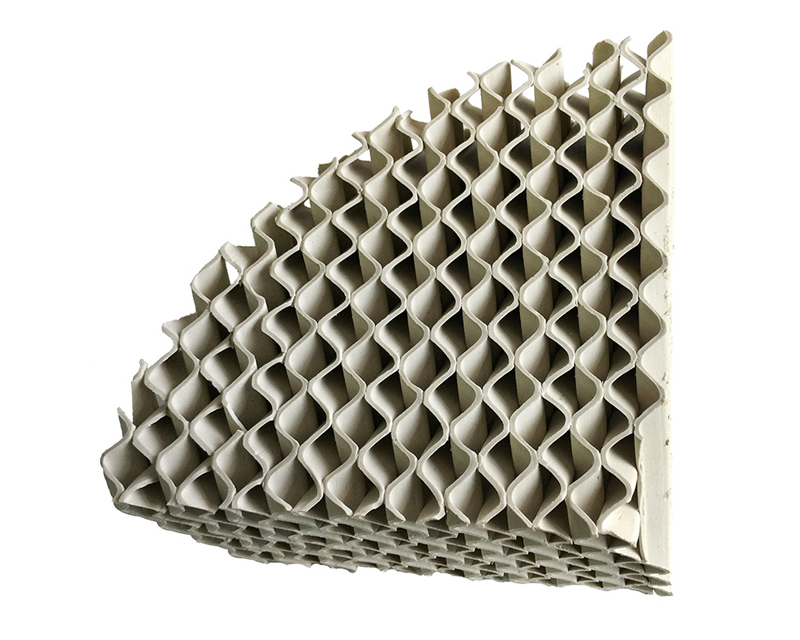

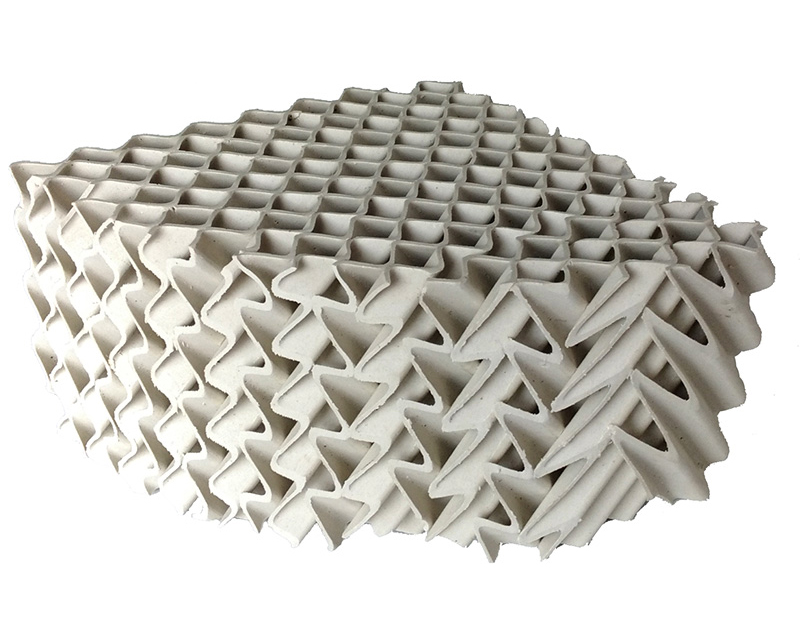

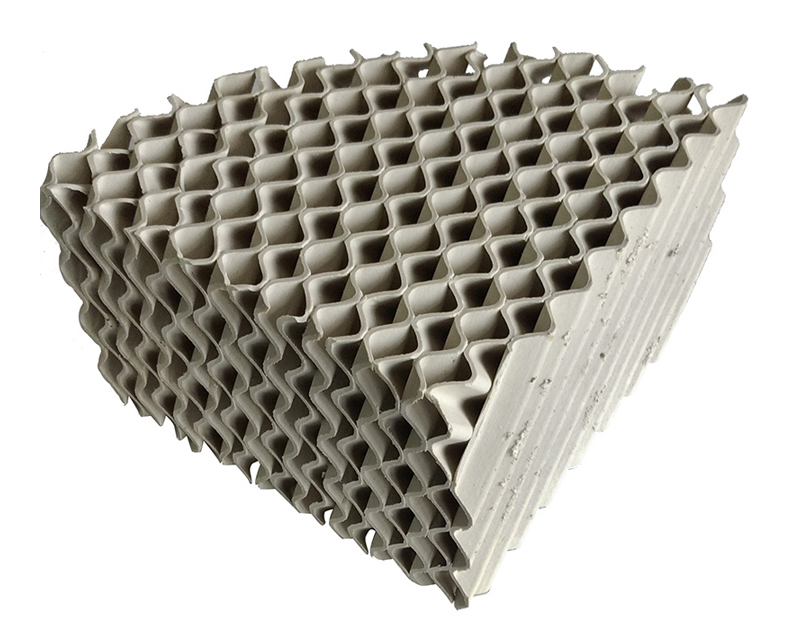

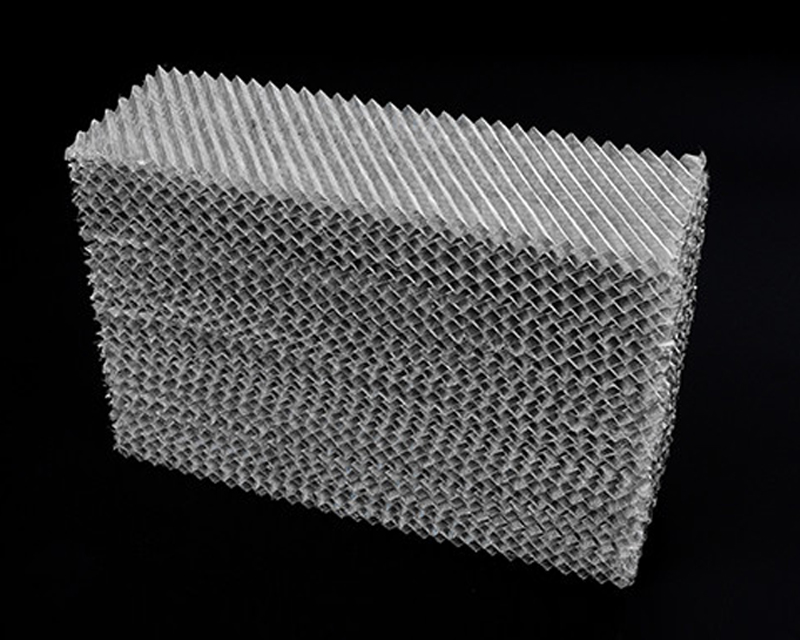

Product overview:

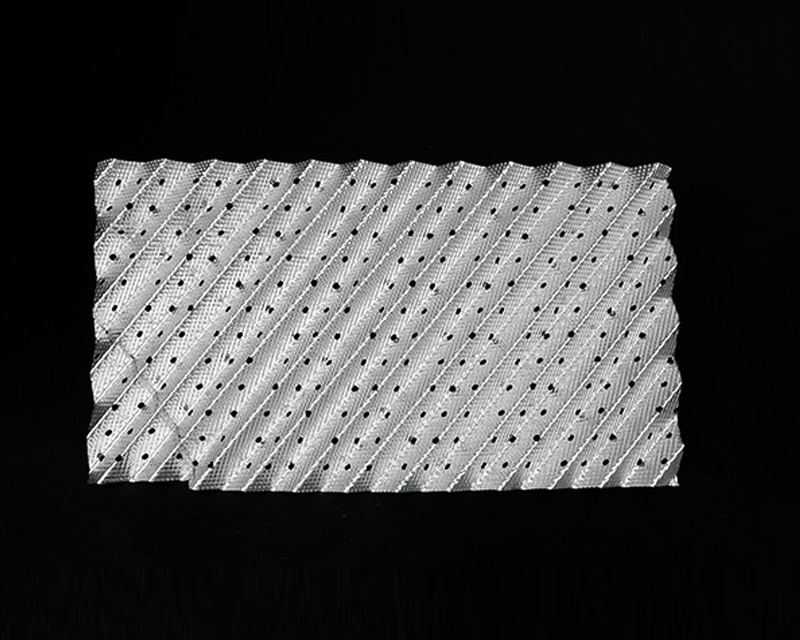

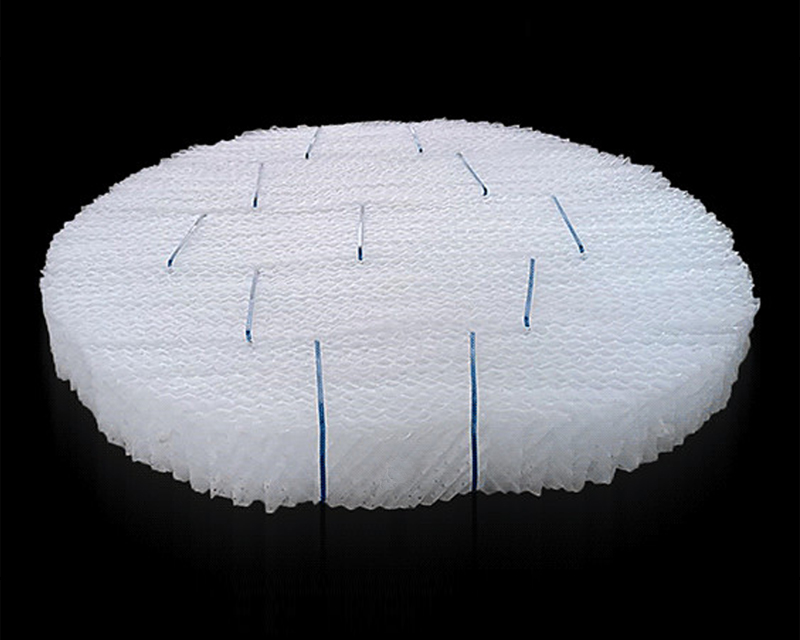

Ceramic corrugated packing consists of many corrugated plates with similar geometric designs. The corrugated plates placed in parallel in the cylindrical tower are called corrugated tower packing. This is a highly efficient packing with several times the separation efficiency of the packing. Compared with random tower packing, their quality has low pressure drop, greater operating flexibility, minimum amplification effect and maximum liquid treatment effect.

Product Features:

●Due to the unique structure of ceramics, it has good hydrophilic properties. The surface can form a very thin liquid film. The turbulence and the inclined tortuous channel of the airflow can promote the airflow without blocking the airflow so that the ceramic packing can match the metal packing. The metal fillers with corrosion resistance and high temperature resistance are incomparable.

●The surface structure has good wetting properties, which can speed up the flow of liquid and minimize the amount of filling liquid. This reduces the chance of overheating, polymerization and coking. This product is processed from high-quality chemical china clay raw materials, can withstand high temperature and pressure, has good chemical stability and high strength. It is an ideal carrier for supporting various types of catalysts.

|

Model

|

Specific surface area

|

Bulk specific gravity

|

Porosity

|

Angle

|

Pressure drop

|

Theoretical number of boards

|

Hydraulic diameter

|

Liquid load

|

Maximum factor

|

|

m²/m³

|

320

|

90

|

°

|

mm Hg/m

|

m-¹

|

mm

|

m³/m²h

|

m/s Kg/m³-¹

|

|

125Y

|

125

|

320

|

90

|

45

|

1.8

|

1.8

|

28

|

0.2-100

|

3.0

|

|

250Y

|

250

|

420

|

80

|

45

|

2

|

2.5

|

12

|

0.2-100

|

2.6

|

|

350Y

|

350

|

470

|

78

|

45

|

2.5

|

2.8

|

10

|

0.2-100

|

2.5

|

|

450Y

|

450

|

520

|

72

|

45

|

4

|

4

|

7

|

0.2-100

|

1.8

|

|

550Y

|

550

|

620

|

74

|

45

|

5.5

|

5-6

|

6

|

0.18-100

|

1.4

|

|

700Y

|

700

|

650

|

72

|

45

|

6

|

7

|

5

|

0.15-100

|

1.3

|

English

English Chinese

Chinese