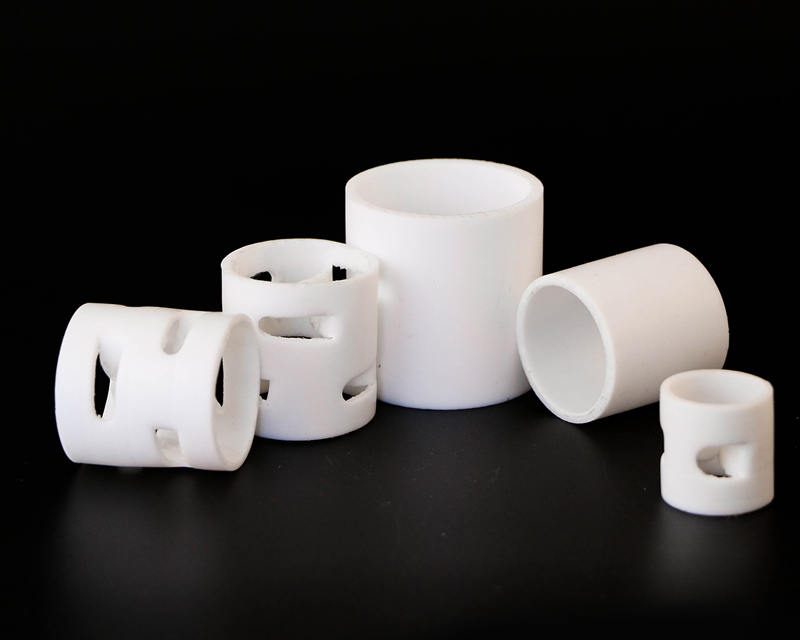

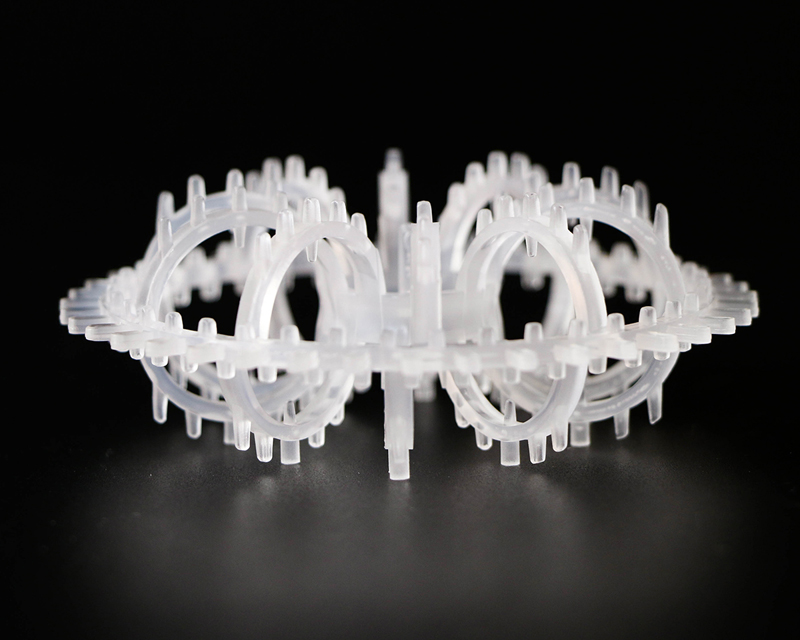

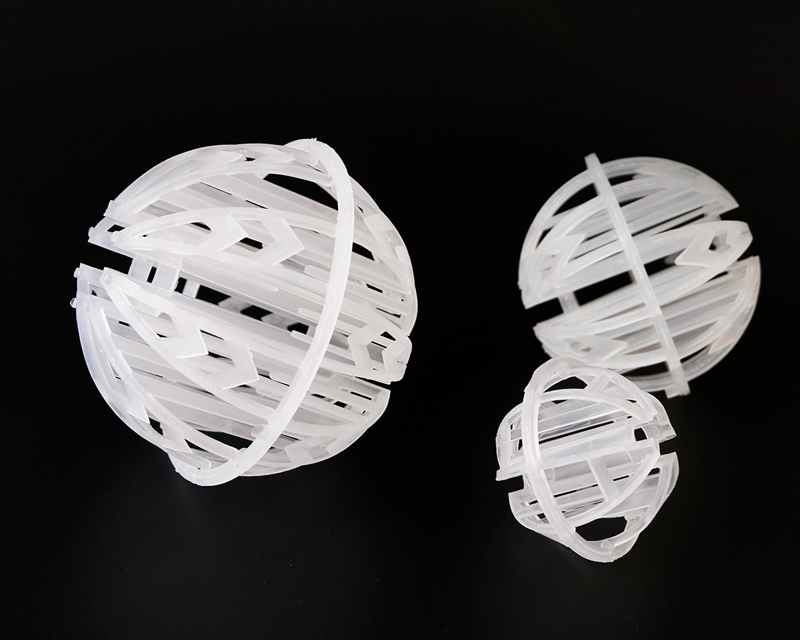

Product overview:

The metal flat-ring random packing tower is particularly suitable for the relative liquid-liquid flow movement stage to reduce the agglomeration of dispersed droplets. The pattern of symmetrical curved arc fins will have a good effect on the uniformity of liquid flow, promote the circulation process of dispersion, convergence and redispersion of the clusters of droplets, effectively reduce the axial backmixing of the packing layer, and improve the liquid and liquid Mass transfer efficiency between. Therefore, the packing has a good technical and cost impact in the liquid-liquid mass transfer extraction process.

Product Features:

●The symmetrical and uniform curved ribs can promote the cyclic process of droplet group dispersion-gathering-re-dispersion, effectively reducing the axial backmixing in the packing layer, thereby improving the mass transfer performance between liquid and liquid phases.

●When this kind of packing is used for liquid-liquid extraction of low interfacial tension system, its performance is obviously better than that of Pall ring, and the mass transfer efficiency should be improved by more than 20%. When used for liquid-liquid extraction in a medium interfacial tension system, the performance of this packing is also significantly better than that of the Pall ring packing. The flat ring packing is especially suitable for liquid-liquid extraction process and also suitable for gas-liquid mass transfer process.

|

Inch/mm mm

|

Bulk weight Kg/m3

|

Number of piles per/m3

|

Specific surface area m2/m3

|

Porosity%

|

Dry packing factor m-1

|

|

16.5*5.5*0.3

|

333

|

600000

|

330

|

95.8

|

375.6

|

|

16.5*5.5*0.4

|

462

|

600000

|

330

|

94.2

|

395.3

|

|

16.5*5.5*0.6

|

718

|

600000

|

330

|

90.9

|

439.2

|

|

25*9*0.3

|

221

|

155000

|

219

|

95.5

|

238.5

|

|

25*9*0.4

|

306

|

155000

|

219

|

96.6

|

246.6

|

|

25*9*0.6

|

477

|

155000

|

219

|

98.4

|

264

|

|

38*12.7*0.6

|

316

|

48000

|

145

|

98.1

|

156.9

|

|

38*12.7*0.8

|

423

|

48000

|

145

|

97.4

|

164

|

|

50*17*0.6

|

250

|

21500

|

115

|

98.3

|

126.4

|

|

50*17*0.8

|

334

|

21500

|

115

|

97.9

|

130.7

|

|

76*25*0.8

|

202

|

5800

|

69

|

98.6

|

74.9

|

|

76*25*1.0

|

256

|

5800

|

69

|

98.2

|

76.5

|

|

76*25*1.2

|

310

|

5800

|

69

|

99

|

78.1

|

English

English Chinese

Chinese