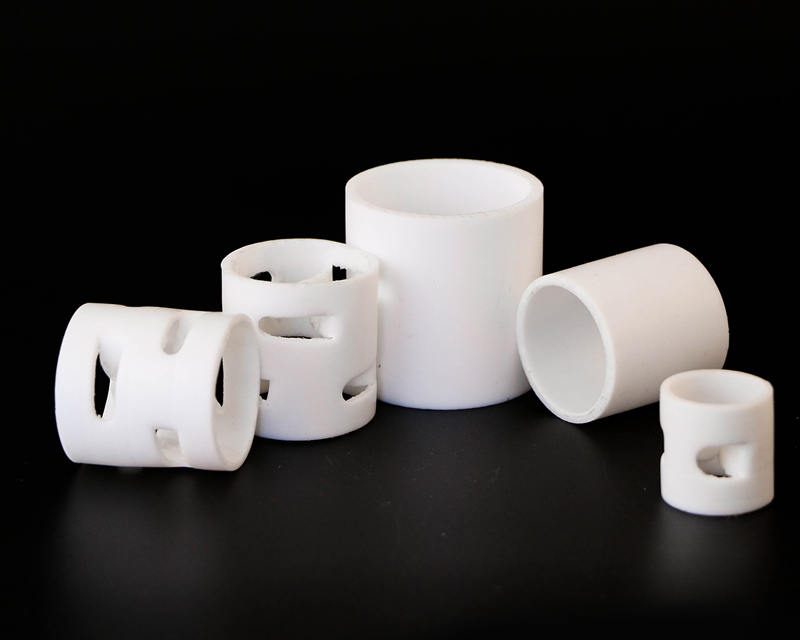

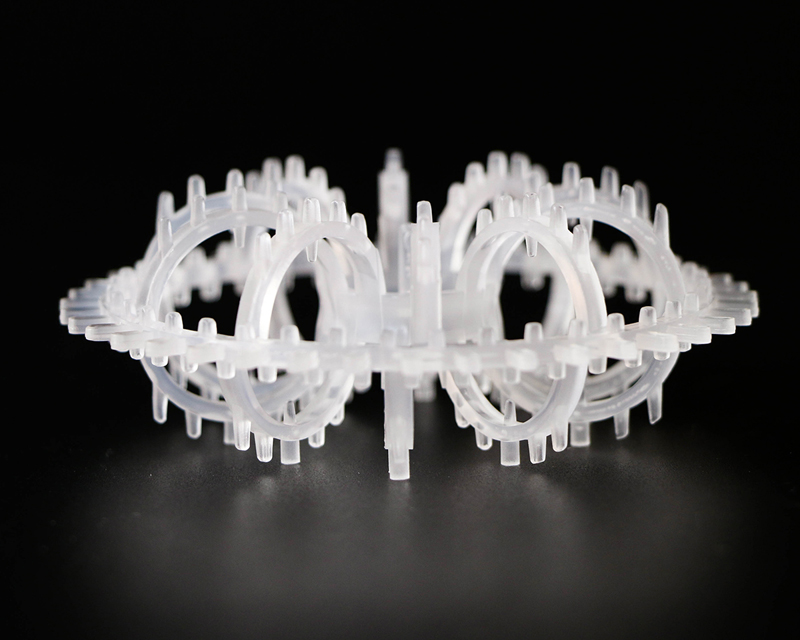

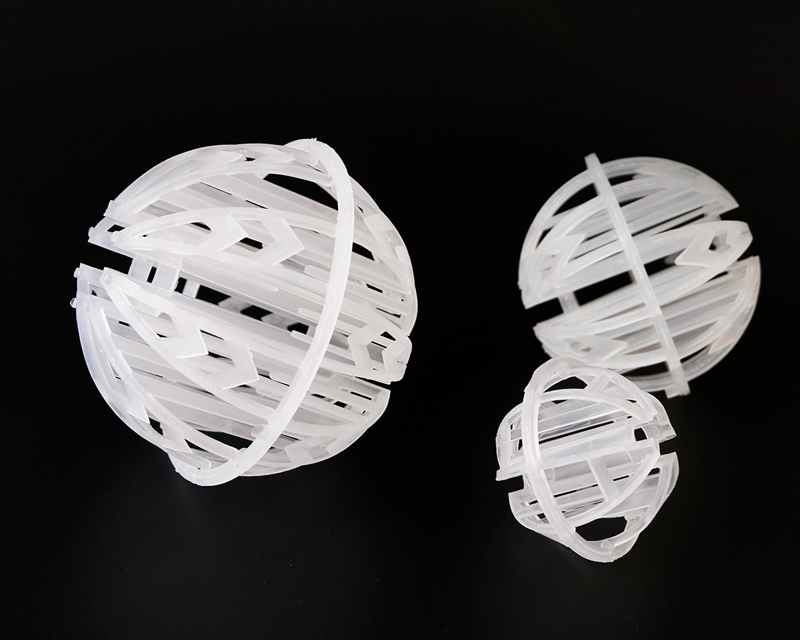

Product overview:

Theta ring Dixon packing is a small particle high-efficiency packing, made of wire mesh, the diameter of the packing is equal to the height. Theta ring packing is mainly used in the laboratory and the separation process of small batch, high-purity products and the development of isotopes. The pressure drop of the θ-ring packing is related to the gas velocity, the amount of liquid spraying, the weight of the material system, the surface tension, the viscosity, and the characteristic factors of the packing. It is also related to the pre-fluid treatment of the packing.

Due to the capillary action of the metal wire mesh, the stagnant amount of theta ring packing is larger than that of similar solid fillers. The surface wetting of theta ring is also more complete than that of the ordinary porcelain ring, and the film formation rate is higher, so the efficiency is higher. The number of theoretical plates of θ-ring packing increases with the increase of gas velocity, and decreases with the decrease of the surface wettability of the packing.

Product Features:

●The number of theoretical plates of the West Tower ring packing decreases with the increase of the packing size and tower diameter. For the packing of small diameter towers, this is more obvious. The increase of the tower diameter reduces the theoretical plate number greatly (in Dr. When /d>10, HETP=0.8-1.2Dr, and when Dr/d>7, the filler rescue rate is significantly reduced, increasing with the increase of gas velocity, and at the same time decreasing with the decrease of the surface cavity moisture rate of the filler. Theta ring domain material is mainly used for the separation process of sub-experimental weight and small batch, high-purity products.

●The theta ring packing is capillary action of the sub-metal wire mesh, the liquid can be well dispersed into a film, and the gas-liquid two kinds of advantages can carry out sufficient mass transfer and heat transfer, which can significantly eliminate the instability of channeling. The pressure drop of the θ-ring packing is related to the gas velocity, the amount of liquid spraying, the weight of the system, the surface tension, the viscosity, the characteristic factors of the packing, and the amount of pre-fluid treatment of the packing. The stagnation of theta ring packing is larger than that of similar solid packings, and the surface wetting is better than that of ordinary porcelain rings. The film formation rate is high, so the separation and rescue rate is also higher.

|

Specification mm

|

Diameter*height mm

|

Mesh

|

Tower diameter mm

|

Theoretical number of boards

Block/meter

|

Bulk density Kg/m3

|

Specific surface area m2/m3

|

|

Φ2

|

2*2

|

100

|

Θ20~35

|

50~60

|

670

|

3500

|

|

Φ3

|

3*3

|

100

|

Θ20~50

|

40~50

|

520

|

2275

|

|

Φ4

|

4*4

|

100

|

Θ20~70

|

30~40

|

380

|

1525

|

|

Φ5

|

5*5

|

100

|

Θ20~100

|

20~30

|

295

|

1180

|

|

Φ6

|

6*6

|

80

|

Θ20~150

|

17~20

|

280

|

1127

|

|

Φ7

|

7*7

|

80

|

Θ20~200

|

14~17

|

265

|

1095

|

|

Φ8

|

8*8

|

80

|

Θ20~250

|

11~14

|

235

|

987

|

|

Φ9

|

9*8

|

80

|

Θ20~300

|

8~11

|

200

|

976

|

|

填料规格mm

|

网目

|

适合塔径mm

|

理论板数

块/米

|

堆积密度

克/升

|

比表面积m2/m3

|

孔隙率%

|

压力降mbar/m

|

|

Φ2*2

|

100

|

Φ10~φ20

|

60~65

|

576

|

3700

|

91

|

30

|

|

Φ3*3

|

100

|

Φ25~φ40

|

50~55

|

460

|

2800

|

93

|

15

|

|

Φ4*4

|

65

|

Φ40~φ70

|

30~32

|

550

|

1700

|

95

|

10

|

|

Φ5*5

|

60

|

Φ50~φ70

|

15~20

|

440

|

1100

|

95

|

10

|

|

Φ6*6

|

60

|

Φ60~φ80

|

12~15

|

365

|

950

|

95

|

10

|

|

Φ8*8

|

60

|

Φ70~φ90

|

10~12

|

284

|

750

|

95

|

8

|

|

Φ10*10

|

60

|

Φ100~φ1200

|

7~8

|

211

|

550

|

95

|

8

|

English

English Chinese

Chinese