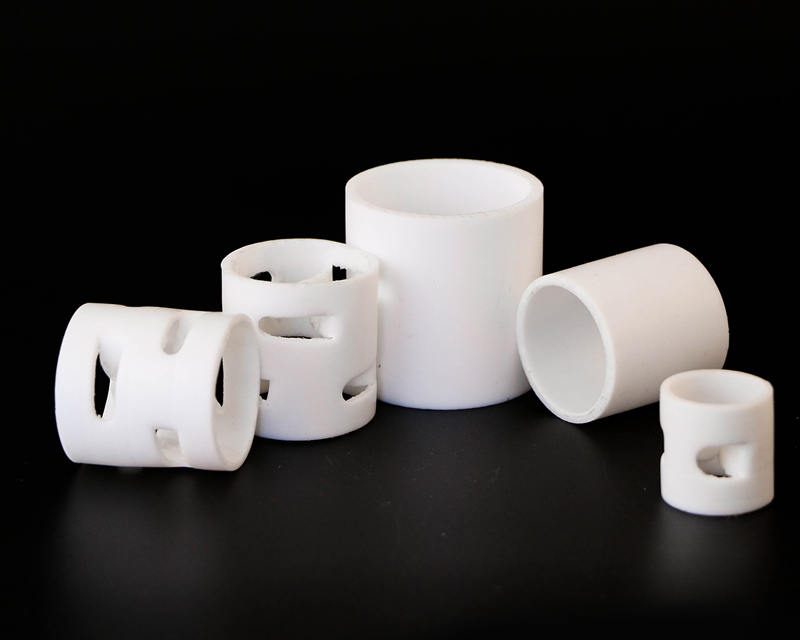

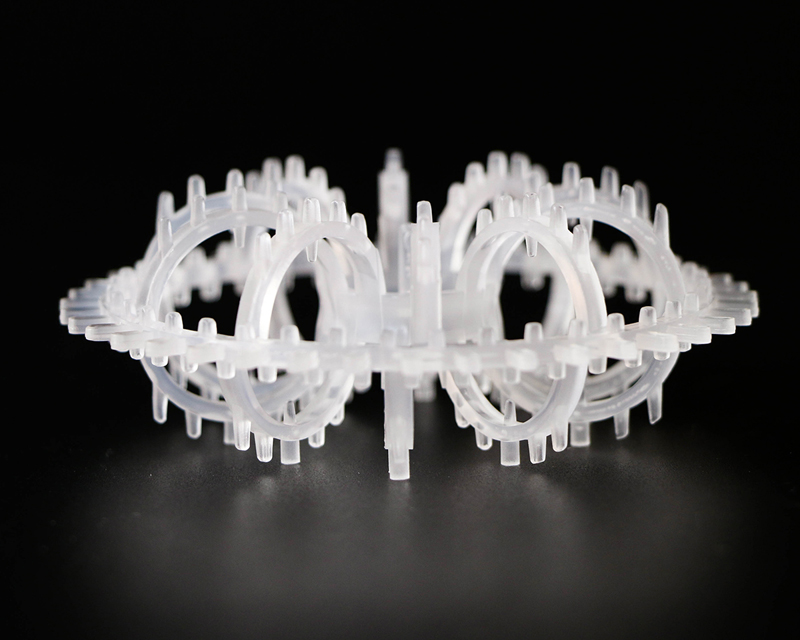

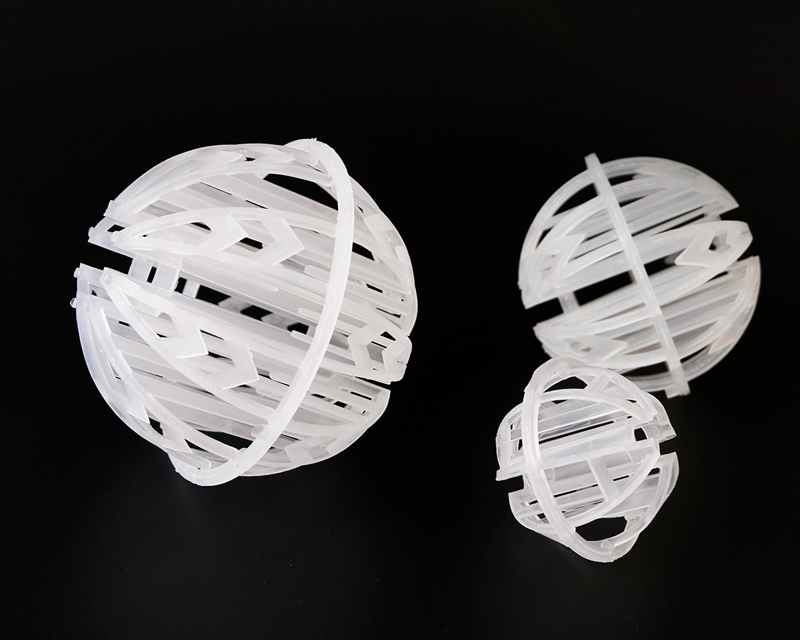

Product overview:

The plastic conjugate ring absorbs the advantages of saddle packing and ring packing, and the structure is more compact and symmetrical. It is equivalent to split the stepped ring in half along the axial direction, and then connect one half of it upside down by 108°. Each semi-circular fin increases the mass transfer surface area, improves the mass transfer performance, and prevents the filler from being loosely packed. Overlapping occurs between the filler bodies. The characteristic is that because the inner ribs are conjugated and have high symmetry, they are very uniform when stacked in the tower and do not overlap in the axial direction. Therefore, the liquid can be evenly distributed on the surface of the filler; the inner ribs of adjacent fillers have many contact points with the surface, which strengthens the convergence and dispersion of the rib liquid, and promotes the renewal of the surface of gas-liquid contact. It has the characteristics of small pressure drop, large gas-liquid contact surface area, and excellent fluid mechanics and mass transfer performance. The polypropylene conjugated packing has a unique structure. When it is installed in the tower, the packing and the tower wall are in point contact, the gap is uniform, and it has the advantages of low fluid resistance (small pressure drop) and large flow. When the fluid passes through the packing layer, The gas coating has good contact, and the tendency of channeling and wall flow is small, so as to achieve the effect of excellent quality-enhancing performance.

Product Features:

●It has the characteristics of high porosity, low pressure drop, low mass transfer unit height, high flooding point, sufficient gas-liquid contact, small specific gravity, and high heat and mass transfer efficiency.

●The operating temperature of these plastic random packing can be 60-280 degrees Celsius. It is widely used in packing towers in petroleum, chemical, chlor-alkali, gas, environmental protection and other industries.

|

Product name

|

Metal conjugate ring

|

|

Material

|

PP, PE, PVC, CPVC, PVDF, PTFE

|

|

Service life

|

3 years

|

|

Size mm

|

Specific surface area m2/m3

|

Porosity%

|

Pieces/m3

|

Bulk weight Kg/m3

|

Dry packing factor m-1

|

|

25*25*1.0

|

185

|

95

|

74000

|

96

|

216

|

|

37*37*1.5

|

142

|

90

|

16320

|

57.7

|

168

|

|

50*40*1.5

|

104

|

80

|

9500

|

52

|

164

|

|

76*76*2.6

|

81

|

95

|

3980

|

64.8

|

94

|

|

100*100*2.0

|

55

|

96

|

1850

|

48

|

62

|

|

Performance

|

Large porosity, low pressure, low mass transfer unit height, high flooding point, sufficient gas-liquid contact, small specific gravity, high mass transfer efficiency

|

|

Advantages

|

1. The special structure enables large circulation, lower pressure and good mechanical strength.

2. Strong corrosion resistance, large porosity, energy saving and environmental protection, low cost, light specific gravity, easy to load and unload.

|

|

Application field

|

The maximum operating temperature of plastic random packing is 280 degrees Celsius, and it is widely used in packing towers in petroleum, chemical, chlor-alkali, gas, and environmental protection industries.

|

|

Properties/Materials

|

PE

|

PP

|

RPP

|

PVC

|

CPVC

|

PVDF

|

|

Density (after injection)

|

0.98

|

0.96

|

1.2

|

1.7

|

1.8

|

1.8

|

|

Operating temperature

|

90

|

>100

|

>120

|

>60

|

>90

|

>150

|

|

Corrosion resistance

|

GOOD

|

GOOD

|

GOOD

|

GOOD

|

GOOD

|

GOOD

|

|

Compressive strength

|

>6.0

|

>6.0

|

>6.0

|

>6.0

|

>6.0

|

>6.0

|

English

English Chinese

Chinese