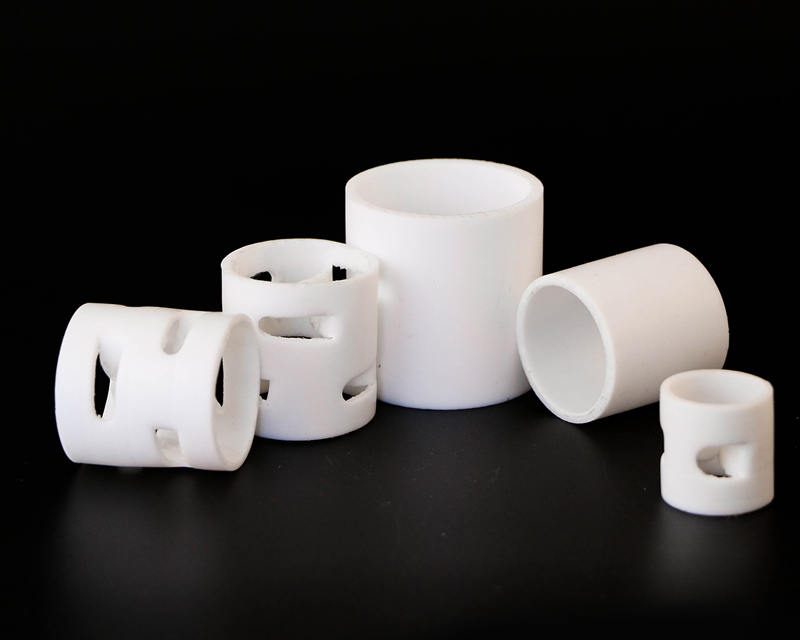

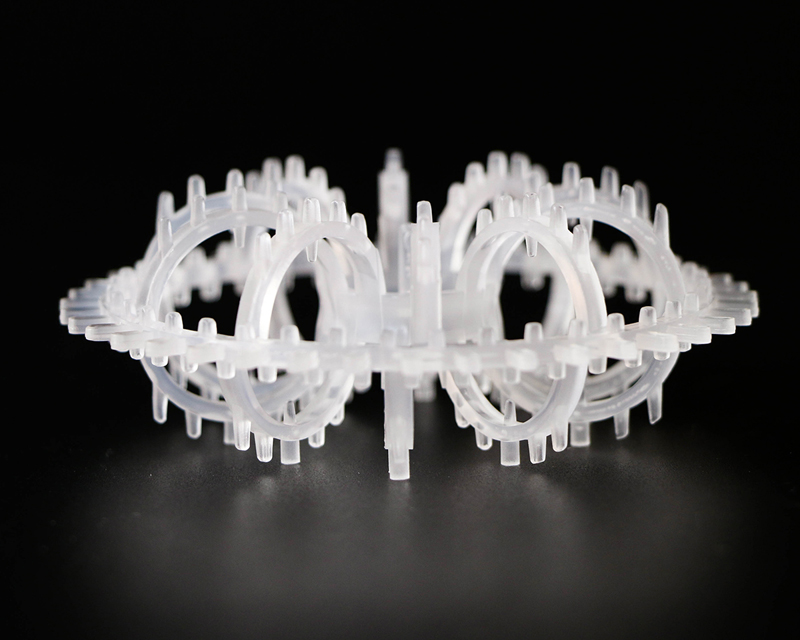

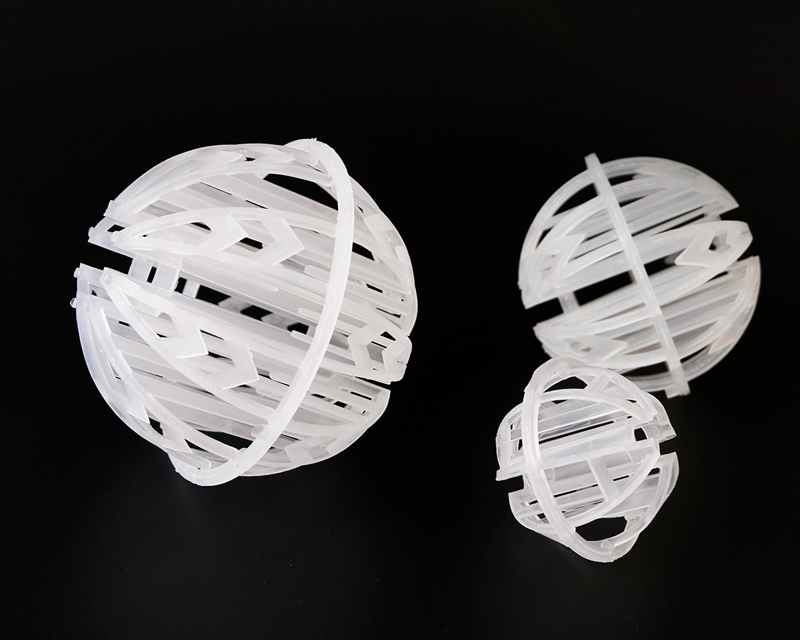

Product overview:

The metal stepped ring tower packing, with one or two beveled edge sides, has better mechanical strength and better gas passing capacity than the Pall ring. In random packed towers, most of the rings are in point contact (not linear contact), resulting in liquid film fluidity and mass transfer efficiency. Kelly's metal process rings are widely used in petroleum, chemical, chlor-alkali, and environmental protection industries.

Product Features:

●The metal step ring is a new type of open-hole packing. Its height is about half of the diameter, one side has a tapered flange, a window hole is opened on the ring wall, and curved blades extend toward the center of the ring. Due to the reduced height and the special structure of the tapered flanging, not only the gas-liquid distribution in the packing layer is improved, but the gas-liquid contact point is increased, which is conducive to the concentration and dispersion of the liquid and the continuous renewal of the membrane surface, so that the mass transfer is strengthened and separated The efficiency is greatly improved.

●Compared with Pall ring packing, the flux of metal step ring packing can be increased by 10-20%, and the pressure can be reduced by 30-40%. The separation efficiency can be improved to different degrees depending on the specific process. So far, there have been more than 1,000 stepped ring packed towers in the world in applications such as absorption, steaming and distillation. According to the specific situation, the step ring can replace Raschig ring, Pall ring, blister plate, float valve plate and sieve plate to achieve the purpose of high efficiency, high yield and energy saving.

|

Model

|

Size mm

|

Specific surface area m2/m3

|

Porosity%

|

Number of piles per/m3

|

Packing factor m-1

|

|

0P

|

17*15*6*0.3

|

427

|

94

|

530,000

|

55

|

|

1P

|

25*22*8*0.3

|

230

|

96

|

150,000

|

40

|

|

1.5P

|

34*29*11*0.3

|

198

|

97

|

60,910

|

29

|

|

2P

|

43*38*14*0.4

|

164

|

97

|

29,520

|

22

|

|

2.5P

|

51*44*17*0.4

|

127

|

97

|

17,900

|

17

|

|

3P

|

66*57*21*0.4

|

105

|

98

|

8,800

|

14

|

|

4P

|

86*76*89*0.4

|

90

|

98

|

5,000

|

10

|

|

5P

|

131*118*41*0.6

|

65

|

98

|

1,480

|

7

|

English

English Chinese

Chinese