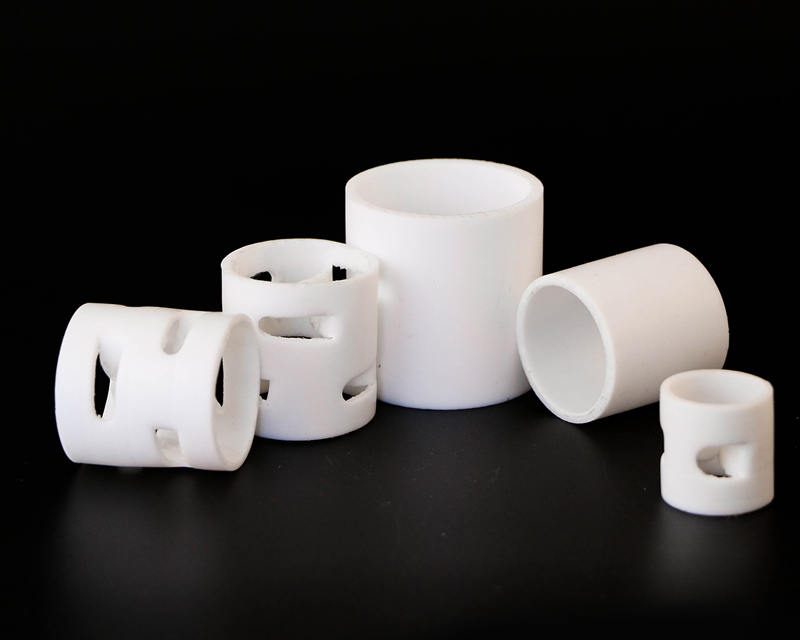

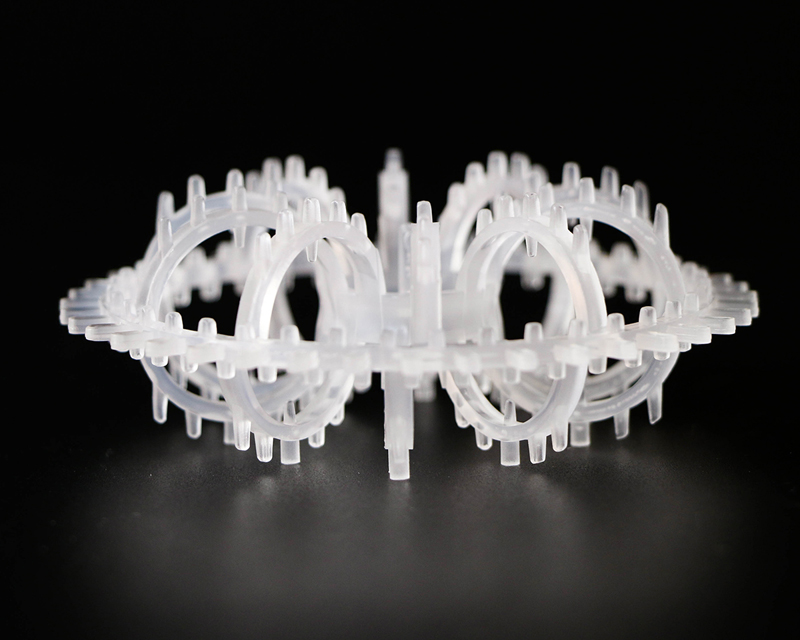

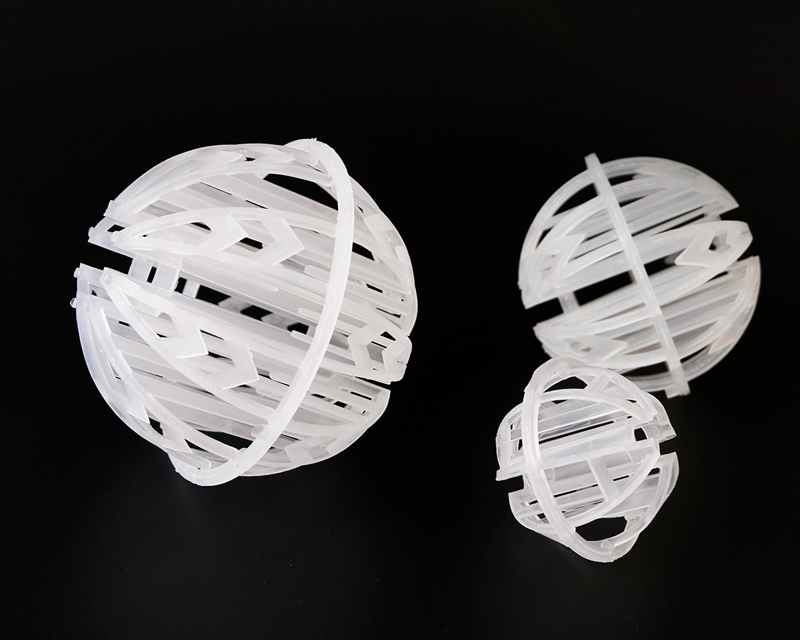

Product overview:

The metal ring rectangular saddle packing was developed by Norton Company in the United States. Its shape is between the ring shape and the saddle shape, so it has the advantages of both. Structurally, the metal rectangular saddle ring filler adds ring ribs to the saddle-shaped foundation to avoid overlap and ensure a certain strength and rigidity. Several small claws are punched out to increase gas-liquid agitation and enhance mass transfer. A unique performance.

Metal rectangular saddles are referred to as Interlocks fillers in China, and enjoy a high reputation in the world. This new type of high-efficiency packing is used to equip a new packed tower. Compared with the plate tower, its height is reduced by 35%, the diameter is reduced by 30%, or the efficiency is increased by 10-30%, and the pressure loss is reduced by 20-60%. Domestic dry distillation instead of wet distillation test research shows that the investment can be reduced by 20%. In short, the use of a new type of ring saddle can increase productivity, reduce energy consumption or cost, and improve separation efficiency.

Product Features:

●Metal saddle ring is a kind of packing, which can be widely used in rectification, absorption and other reactions.

●The metal rectangular saddle ring can be used in both vacuum towers and high-pressure towers.

●Metal saddle ring can be applied to mass transfer towers with different diameters. It is often used in vacuum towers where the low pressure drop is critical. At the same time, it is often used in high-pressure towers, and its capacity greatly exceeds typical trays.

|

Size mm

|

Bulk weight kg/m

|

Number of piles per/m3

|

Specific surface area m2/m

|

Porosity%

|

Dry packing factor m-1

|

|

16.5*10.6*0.25

|

223

|

324110

|

275

|

97.2

|

300.2

|

|

16.5*10.6*0.3

|

263

|

324110

|

275

|

96.7

|

304.9

|

|

25.9*12.6*0.25

|

163

|

127180

|

415

|

4.8

|

489.2

|

|

25.9*12.6*0.3

|

192

|

127180

|

344

|

95.5

|

393.2

|

|

25.9*12.6*0.4

|

266

|

127180

|

199

|

96.6

|

221.0

|

|

35.4*18.8*0.25

|

124

|

51180

|

151

|

98.4

|

158.3

|

|

35.4*18.8*0.3

|

146

|

51180

|

151

|

98.1

|

159.7

|

|

35.4*18.8*0.4

|

203

|

51180

|

151

|

97.4

|

163.2

|

|

48.5*28.6*0.3

|

9000

|

15550

|

97

|

98.8

|

101.0

|

|

48.5*28.6*0.4

|

132

|

15550

|

97

|

98.3

|

102.5

|

|

48.5*28.6*0.5

< /div>

|

169

|

15550

|

97

|

97.9

|

103.9

|

|

67*37*0.4

|

113

|

9000

|

84

|

98.6

|

87.3

|

|

67*37*0.5

|

145

|

9000

|

84

|

98.2

|

88.4

|

|

76.5*42.5*0.4

|

83

|

4690

|

61

|

99.0

|

62.9

|

|

76.5*42.5*0.4

|

106

|

4690

|

61

|

98.7

|

63.5

|

English

English Chinese

Chinese