Product overview:

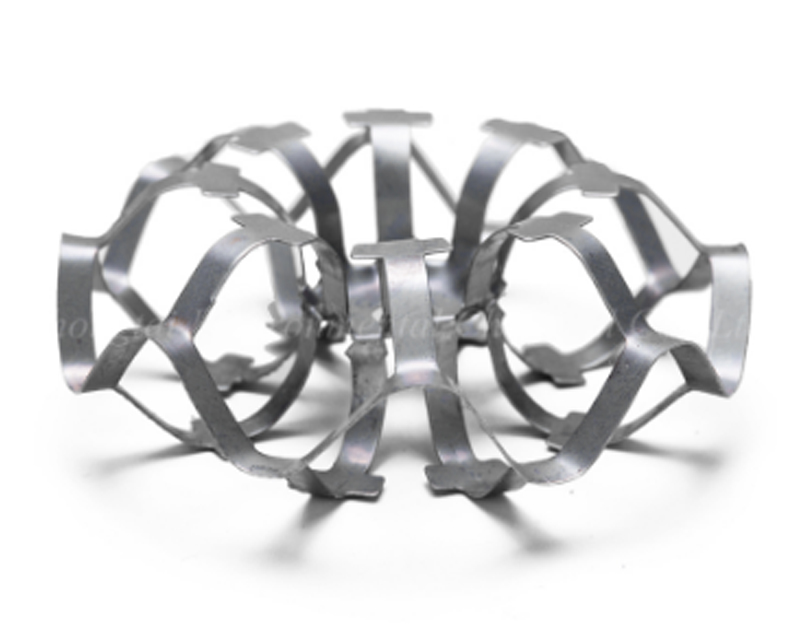

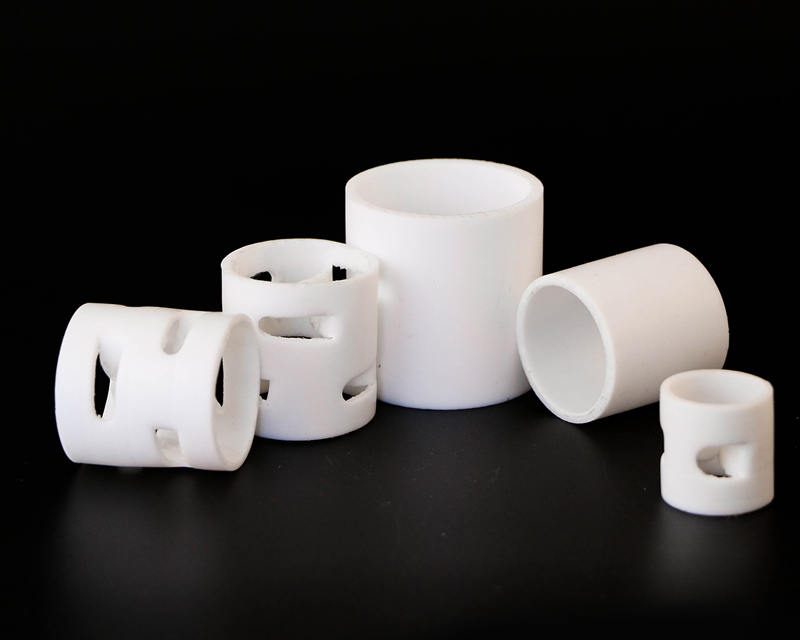

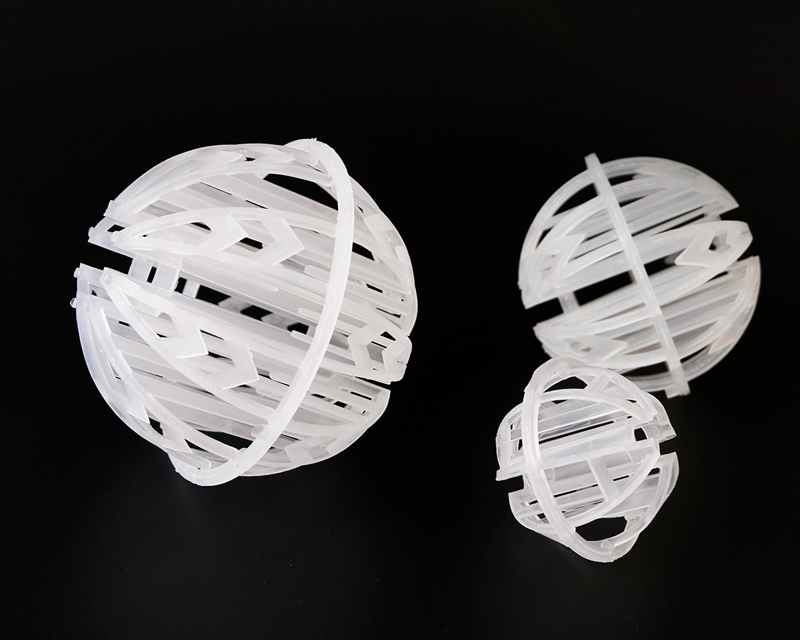

Metal Taylor garland packing is stamped and stretched into a specific calendered mesh with a thin metal plate, with regular diamond meshes on the surface, maintaining the geometric rules of the wire mesh corrugated packing. The garland packing can be processed by various materials, and the material selection surface is more than that of the wire mesh packing. Wide, so the corrosion resistance is good. Garland packing is divided into plastic rosette packing and metal rosette packing. Among them, plastic rosette packing appeared earlier and is mostly used in gas scrubbing and purification towers.

Product Features:

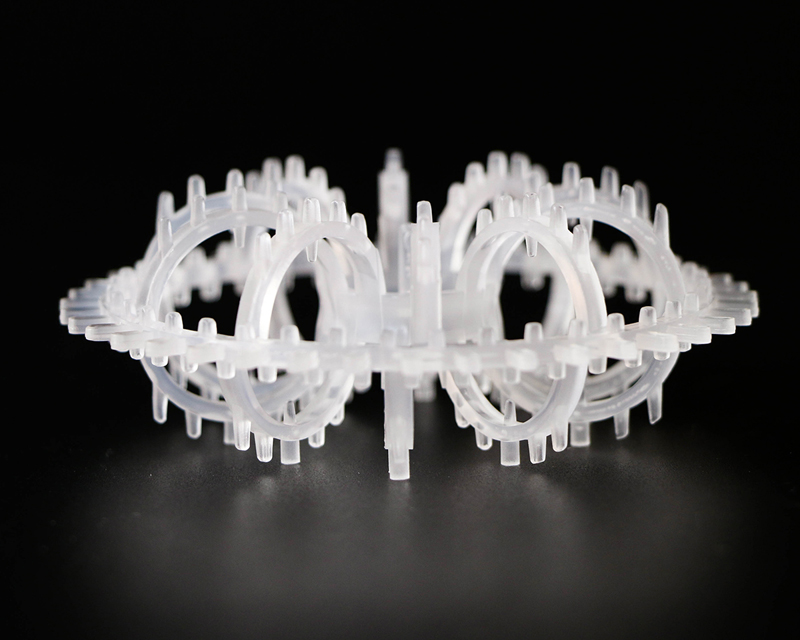

●The filler has a large porosity and is not easy to be blocked. It also has the advantages of large flux and low resistance. The rosette packing is also called the plum rosette packing, which is made up of many rings, because the gap of the packing can have a higher holding capacity. Liquid volume, due to the relatively high stagnant volume in the gaps of the packing, the liquid residence time in the tower can be longer, thereby increasing the gas-liquid contact time and improving the mass transfer efficiency of the packing. Polypropylene packing has the characteristics of large porosity, low pressure drop and mass transfer unit height, high flooding point, sufficient vapor-liquid contact, low specific gravity, and high mass transfer efficiency. It is mostly used in gas scrubbing and purification towers.

●Compared with polypropylene rosettes, reinforced polypropylene rosettes have longer service life, better chemical resistance, and improved mechanical properties, creep resistance and dimensional stability. Our company chooses the reinforced polypropylene fiberglass produced by Beijing Research Institute of Chemical Industry. The product has a temperature resistance of 127°C and a heat distortion temperature of 160°C. It has high strength, chemical resistance, good electrical insulation, impact resistance and many other excellent properties, and good toughness.

●Metal rosette packing has a higher liquid holding capacity in the gap of the packing, which can make the residence time of the liquid in the tower longer, thereby increasing the contact time of the gas-liquid two-phase, and improving the mass transfer efficiency of the packing.

Size

|

Number of piles

|

Specific surface area

|

Porosity

|

50*25*0.8

|

19180

|

112.8

|

96.2

|

75*75*1.0

|

5460

|

64.1

|

97.3

|

100*45*1.2

|

2520

|

53.4

|

97.3

|

English

English Chinese

Chinese