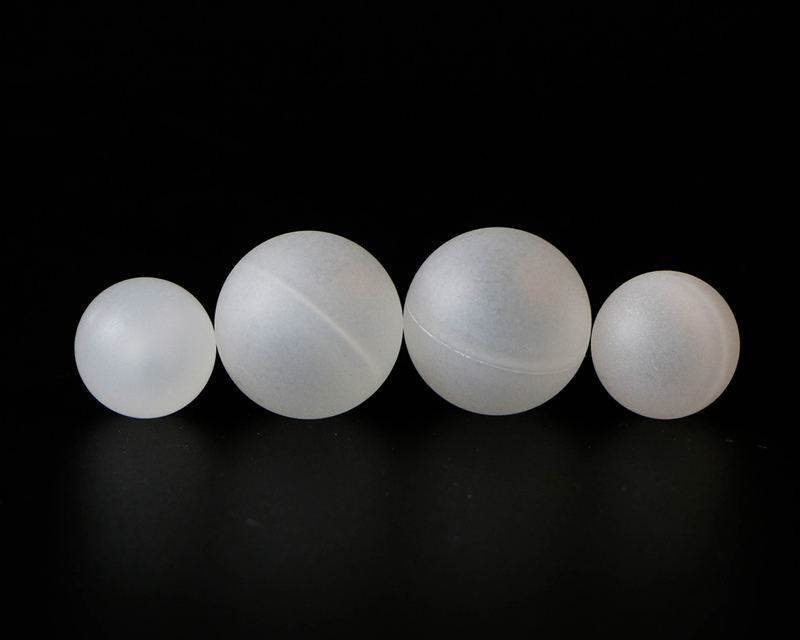

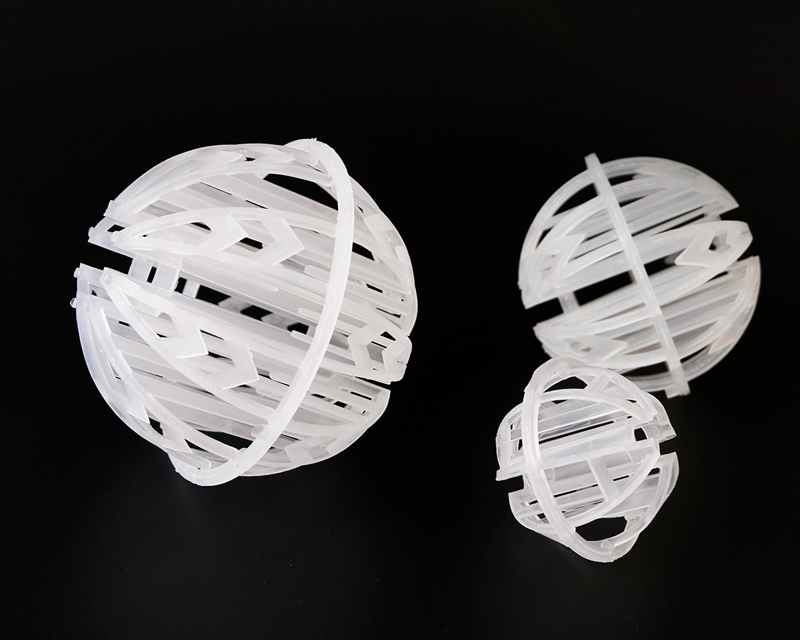

4.1 Plastic Hollow Ball

This ball is made by blow molding technology. So there are no cracks in this ball. Traditionally, this ball is used for water treatment. When millions of plastic hollow spheres float on the surface of the liquid, the spheres automatically form a liquid-covered surface. The covered surface provides a very effective barrier and reduces heat consumption in the liquid and the surrounding environment. At present, according to the continuous development and innovation of scientists, the application of this ball will be more extensive. Such as preventing birds from stacking on and around the liquid surface, building nests, using as a check valve ball in flow control applications, and damping vibration in the construction field.

Main features: high porosity, heat resistance, chemical corrosion resistance, low pressure drop and mass transfer unit height, high flooding point, sufficient vapor-liquid contact, small specific gravity, stable center of gravity, high mass transfer efficiency, good absorption effect, and purification effect High rate and other features

Application: Suitable for various horizontal acid storage tanks in petroleum, chemical, chlor-alkali, gas, smelting, environmental protection, and electric power enterprises Pickling, electroplating, electrophoresis, anodic oxidation, wet electrolysis, various horizontal acid storage tanks, etc., to suppress the volatilization and splashing of acid mist during the operation

Keywords: hollow floating ball; table tennis hollow floating ball; polypropylene PP hollow floating ball filler; 25mmPP hollow floating ball; PP hollow floating ball; demineralized water tank PP hollow ball

Diameter mm

|

Heavy gg

|

Number of piles/ft²

|

Number of piles/m²

|

10

|

0.2

|

1076

|

11600

|

20

|

1.0

|

270

|

2900

|

25

|

1.5

|

172

|

1850

|

38

|

4.5

|

74

|

800

|

45

|

7.0

|

53

|

570

|

50

|

8.0

|

43

|

465

|

70

|

16.0

|

22

|

235

|

100

|

40

|

10

|

116

|

150

|

100

|

4.8

|

51.5

|

English

English Chinese

Chinese