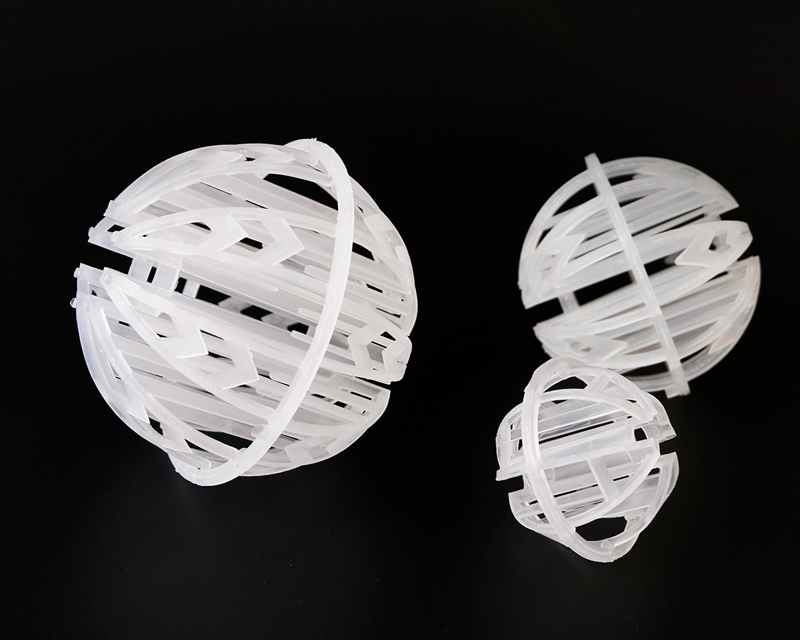

1.17 Screen packing (Fxp-HD/Q-Pack)

It is considered a revolutionary coalescing medium that can separate grease from water containing suspended particles. The large surface area makes it very suitable as a biological carrier medium. The dense pore distribution of each layer and the interlocking of the layers will prompt small oil-free molecules to quickly contact the lipophilic surface, and finally form large oil droplets, which greatly shortens the oil-water separation time. Vertical rods are distributed at the bottom of each layer to speed up the rapid fall of oil and water without clogging. The special design makes HD/Q-pack an ideal carrier for odor control scrubbers and oil-water separators.

Main features: biological treatment, filtration, seawater desalination, pretreatment scrubber and gas cooling tower packing, stainless steel oil-water separation, wastewater treatment, water treatment for aquariums and aquaculture. Used for biological treatment filtration seawater desalination pretreatment, greatly increasing the effective gas-liquid contact area, high mass transfer efficiency, and relatively small defogging layer

Applications: Treatment of scrubbers and gas cooling tower packing, stainless steel oil-water separation, wastewater treatment, water treatment in aquariums and aquaculture.

Keywords: plastic structured packing, plastic screen packing, screen packing

Size mm

|

Specific surface area ft²/ft³

|

Number of drops

|

Bulk weight Kg/m³

|

Minimum opening size

|

Porosity%

|

305*305*305

|

132

|

75000/ft³

|

130

|

0.16"*0.16"

|

87.8

|

40*40*40

|

612 m²/m³

|

No data

|

170

|

0.07"*0.07"

|

No data

|

English

English Chinese

Chinese