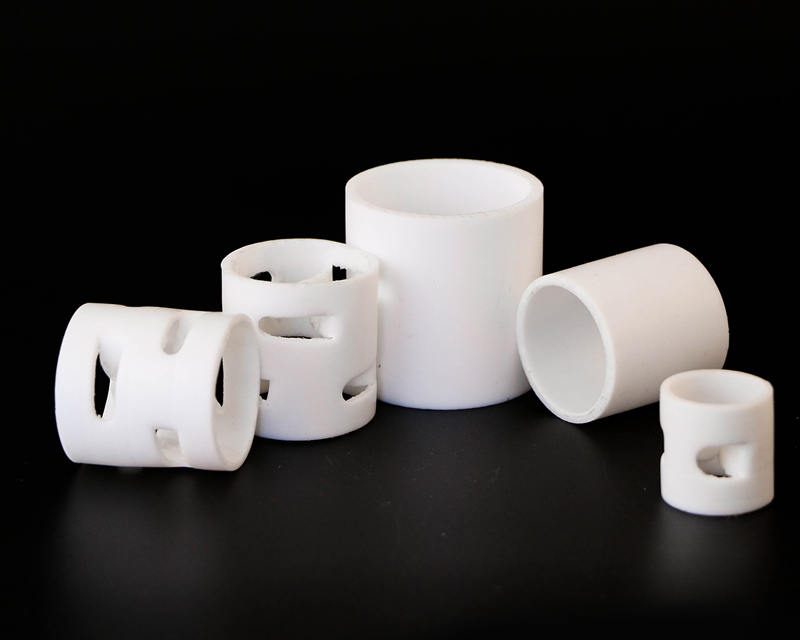

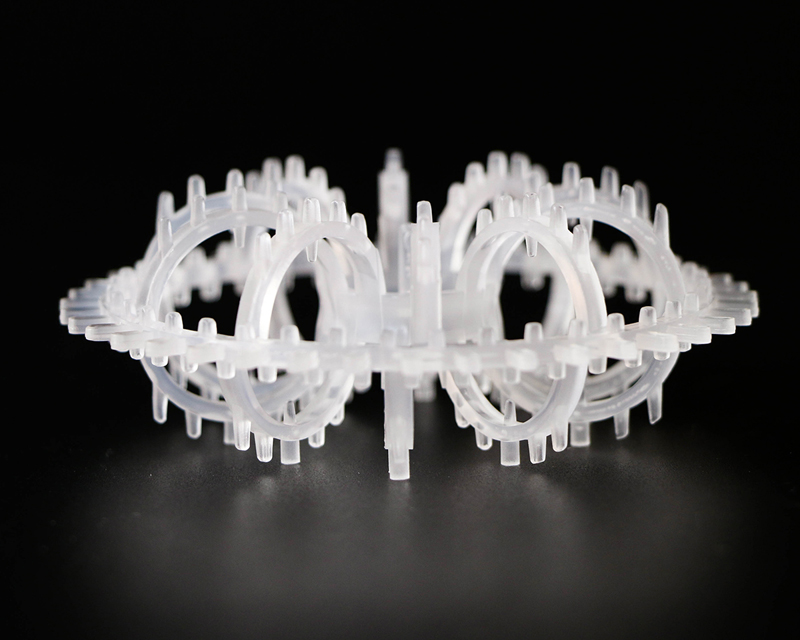

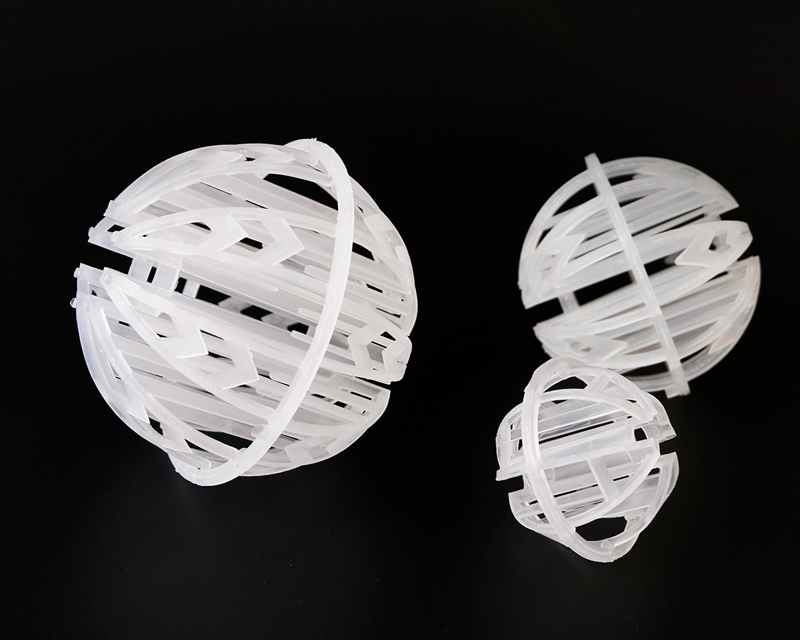

Product overview:

The plastic Pall ring is a kind of open-hole ring packing with equal height and diameter. It is based on the Raschig ring packing. The ring wall is opened with windows. The positions of the upper and lower windows are staggered oppositely. The opening area accounts for about 30% of the total area of the ring wall. Without increasing the surface area of the filler, the gas-liquid two-phase flow in the filler layer is greatly improved, and the fluid mechanics and mass transfer performance of the filler are improved. Its shape and structure can be divided into the inner ribs, which are Yonzi-shaped, called plastic Pall rings (m); the inner ribs are in the shape of a well, and are called plastic Pall rings (wells).

Since the Pall ring packing has many windows on the ring wall, so that the gas and liquid in the packed tower can pass through the windows freely, the gas and liquid distribution in the packing layer is greatly improved compared with the Raschig ring , In particular, the inner surface of the packing ring is easily wetted by liquid, so that the inner surface can be fully utilized. Compared with Raschig ring packing, the Pall ring packing of the same material and the same specification not only has a larger passing capacity and a lower pressure drop, but also improves the separation efficiency of the tower and increases the operating flexibility. . Generally, under the same pressure drop, the processing capacity of the Pall ring packing is increased by more than 50% compared with the Raschig ring; at the same processing volume, the pressure drop can be reduced by half, and the mass transfer efficiency can be increased by about 20%. Compared with the Raschig ring, this packing has the characteristics of large production capacity, strong resistance, and large operating flexibility. In general, the pressure drop can be 50% larger than the Raschig ring under the same pressure drop, and the pressure drop is higher than the Raschig ring under the same treatment. The ring is 50%-70% smaller, and the height can also be reduced by the same tower. The use of plastic Pall ring can be 20%-40% of the packing volume than the Raschig link.

Product Features:

●The Pall ring is greatly improved on the Raschig ring. Although the outer diameter of the ring is also equal to the height, two rows of windows with inward tongues are opened on the ring wall, and each window hole has 5 tongues. This structure improves the gas-liquid distribution and makes full use of the inner surface of the ring. Compared with the Raschig ring, the processing capacity can be more than 50% larger, and the pressure can be reduced by half.

●Generally, the opening area accounts for about 30% of the total area of the ring wall. Without increasing the surface area of the filler, the gas-liquid two-phase flow in the filler layer is greatly improved, and the fluid mechanics and mass transfer performance of the filler are improved.

●Plastic Pall ring has the characteristics of reduced pressure, large flux and high efficiency.

●Low pressure drop and mass transfer unit height, high flooding point, sufficient vapor-liquid contact, low specific gravity, high mass transfer efficiency, etc.

|

Product name

|

Plastic Pall Ring

|

|

Material

|

PP/RPP/PVC/CPVC/PVDF/PTFE,PTFE

|

|

Service life

|

3 years

|

|

Size mm

|

Specific surface area m2/m3

|

Porosity%

|

Pieces/m3

|

Bulk weight Kg/m3

|

Dry packing factor m-1

|

|

16*16*1

|

188

|

91

|

170000

|

85

|

275

|

|

25*25*1.2

|

175

|

90

|

53500

|

69

|

239

|

|

38*38*1.4

|

115

|

89

|

15800

|

69

|

220

|

|

50*50*1.5

|

93

|

90

|

6500

|

52

|

127

|

|

76*76*2.6

|

73.2

|

92

|

1927

|

48

|

94

|

|

100*100*3

|

52.8

|

94

|

1000

|

48

|

82

|

|

Performance

|

Large porosity, low pressure, low mass transfer unit height, high flooding point, sufficient gas-liquid contact, small specific gravity, high mass transfer efficiency

|

|

Advantages

|

1. The special structure enables large circulation, lower pressure and good mechanical strength.

2. Strong corrosion resistance, large porosity, energy saving and environmental protection, low cost, light specific gravity, easy to load and unload.

|

|

Application field

|

The maximum operating temperature of plastic random packing is 280 degrees Celsius, and it is widely used in packing towers in petroleum, chemical, chlor-alkali, gas, and environmental protection industries.

|

|

Properties/Materials

|

PE

|

PP

|

RPP

|

PVC

|

CPVC

|

PVDF

|

|

Density (after injection)

|

0.98

|

0.96

|

1.2

|

1.7

|

1.8

|

1.8

|

|

Operating temperature

|

90

|

>100

|

>120

|

>60

|

>90

|

>150

|

|

Corrosion resistance

|

GOOD

|

GOOD

|

GOOD

|

GOOD

|

GOOD

|

GOOD

|

|

Compressive strength

|

>6.0

|

>6.0

|

>6.0

|

>6.0

|

>6.0

|

>6.0

|

English

English Chinese

Chinese