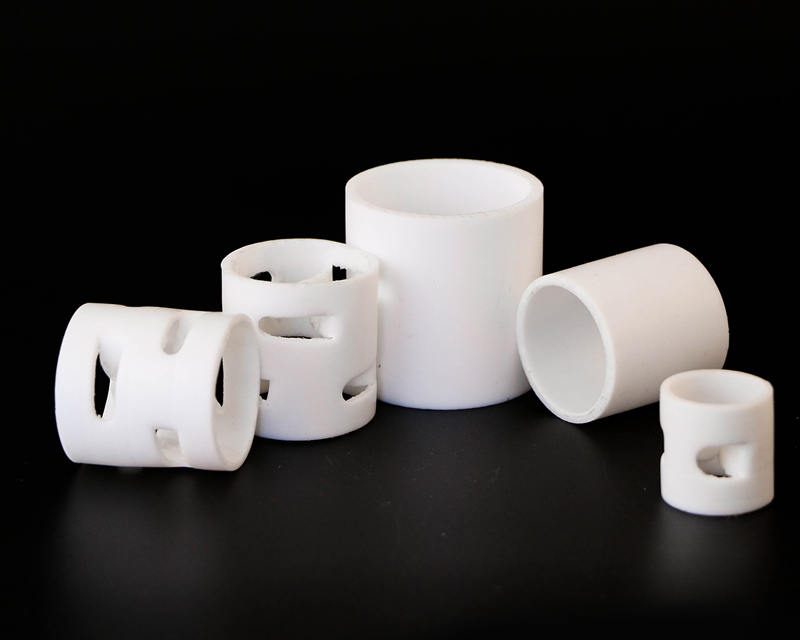

Product overview:

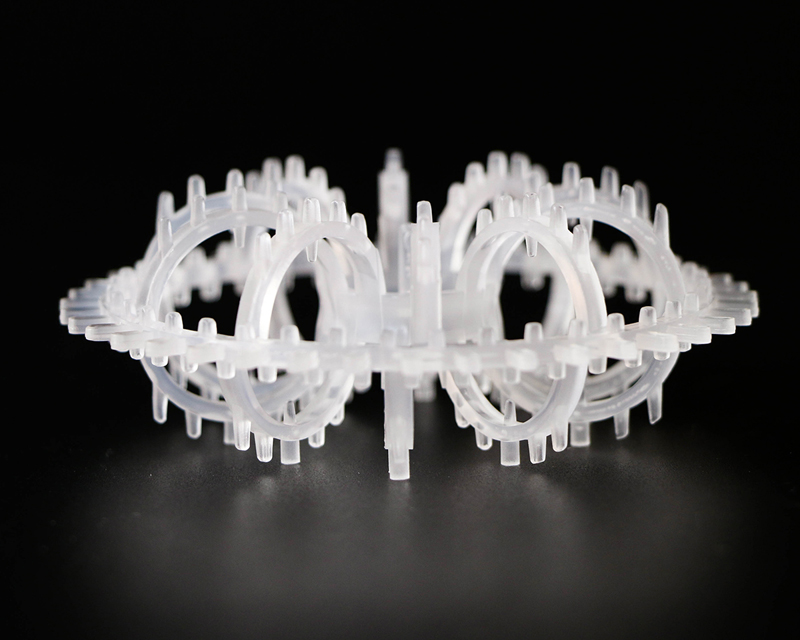

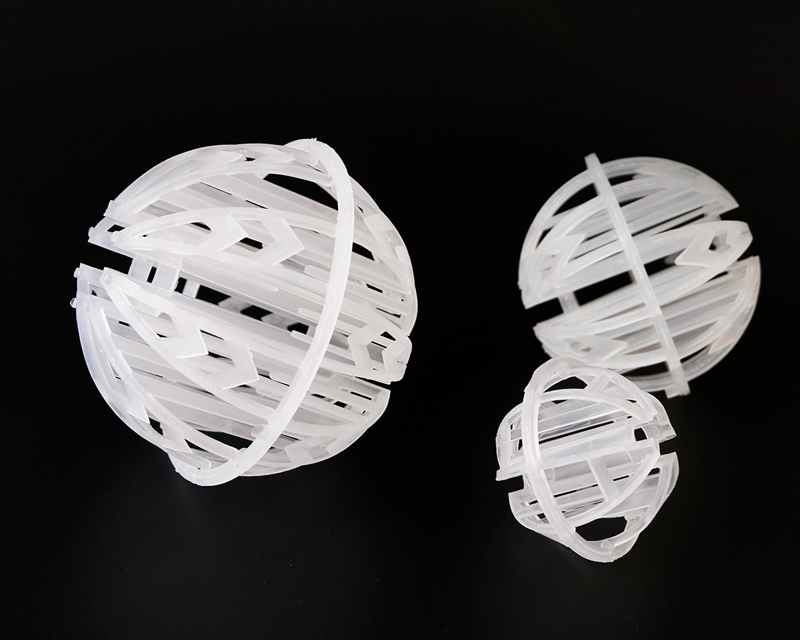

The plastic ladder ring is made of PP, PE, PP, PVC, CPVC, PVDF and other materials. It was invented by the British MTL company, so it is also called CMR. The side end of the plastic step ring packing increases the flanging, which can not only increase the mechanical strength of the packing ring, but also because the plastic step ring packing has destroyed the symmetry of the packing structure, thus increasing the orientation probability of the packing when the packing is placed. Also, due to the influence of the flanging, the contact between the annular gaps of the filler during the stacking of the stepped ring filler is changed from linear contact to point contact. Therefore, the expected stepped ring packing not only increases the gap between the packing particles and reduces the resistance of the gas passing through the packing layer, but these contact points can also be the convergence and dispersion points of the liquid flowing along the packing surface, thereby promoting the surface of the liquid film The renewal is conducive to the improvement of the mass transfer efficiency of the packing.

Product Features:

●Large flux and small pressure drop: Due to the packing structure and packing characteristics, the gas passage in the packing layer is more uniform and the return path becomes shorter, so the pressure drop of the packing layer is not increased when increasing the gas flux of the coating layer.

●High efficiency: The flanging of the plastic step ring packing can not only increase the gap of the packing layer, but also make the gap uniform. The uniform gap is conducive to the formation of a more uniform and effective liquid film on the surface of the filler, providing a good channel for vapor and liquid , Does not exist on the surface or dry surface of the Pall ring or saddle-shaped packing, so the mass transfer efficiency of the stepped ring packing is higher than the above two kinds of packing.

●Large operating flexibility: Because the step ring packing greatly improves the uniform distribution of liquid and gas-liquid contact conditions inside the packing layer, its operating range has a longer growth, and its L/G can be operated in the range of 50-0.05 .

|

Product name

|

Plastic step ring

|

|

Material

|

PP, PE, PVC, CPVC, PVDF, PTFE

|

|

Service life

|

3 years

|

|

Size mm

|

Specific surface area m2/m3

|

Porosity%

|

Pieces/m3

|

Bulk weight Kg/m3

|

Dry packing factor m-1

|

|

16*8.9*1

|

370

|

85

|

299136

|

135.6

|

602.6

|

|

25*12.5*1.2

|

228

|

90

|

81500

|

65

|

312.8

|

|

38*19*1.2

|

132.5

|

91

|

27200

|

54

|

175.8

|

|

50*25*1.5

|

114.2

|

92.7

|

10740

|

43

|

143.1

|

|

76*37*2.6

|

90

|

92.9

|

3420

|

44

|

112.3

|

|

Performance

|

Large porosity, low pressure, low mass transfer unit height, high flooding point, sufficient gas-liquid contact, small specific gravity, high mass transfer efficiency

|

|

Advantages

|

1. The special structure enables large circulation, lower pressure and good mechanical strength.

2. Strong corrosion resistance, large porosity, energy saving and environmental protection, low cost, light specific gravity, easy to load and unload.

|

|

Application field

|

The operating temperature of plastic random packing is 280 degrees Celsius, and it is widely used in packing towers in petroleum, chemical, chlor-alkali, gas, and environmental protection industries.

|

|

Properties/Materials

|

PE

|

PP

|

RPP

|

PVC

|

CPVC

|

PVDF

|

|

Density (after injection)

|

0.98

|

0.96

|

1.2

|

1.7

|

1.8

|

1.8

|

|

Operating temperature

|

90

|

>100

|

>120

|

>60

|

>90

|

>150

|

|

Corrosion resistance

|

GOOD

|

GOOD

|

GOOD

|

GOOD

|

GOOD

|

GOOD

|

|

Compressive strength

|

>6.0

|

>6.0

|

>6.0

|

>6.0

|

>6.0

|

>6.0

|

English

English Chinese

Chinese