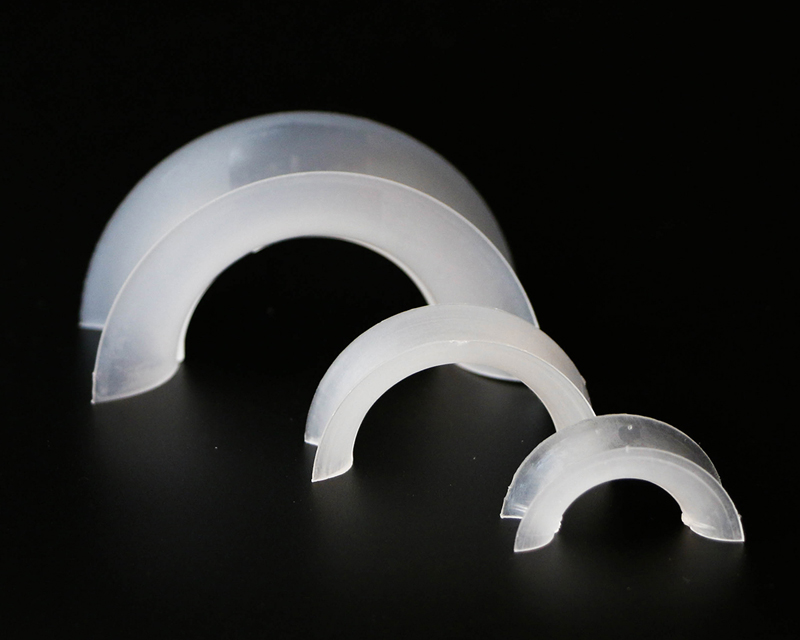

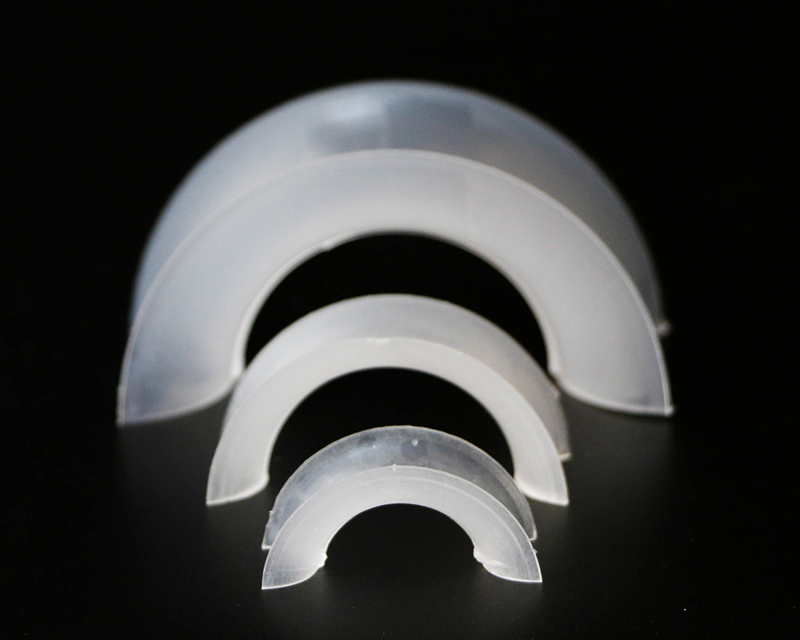

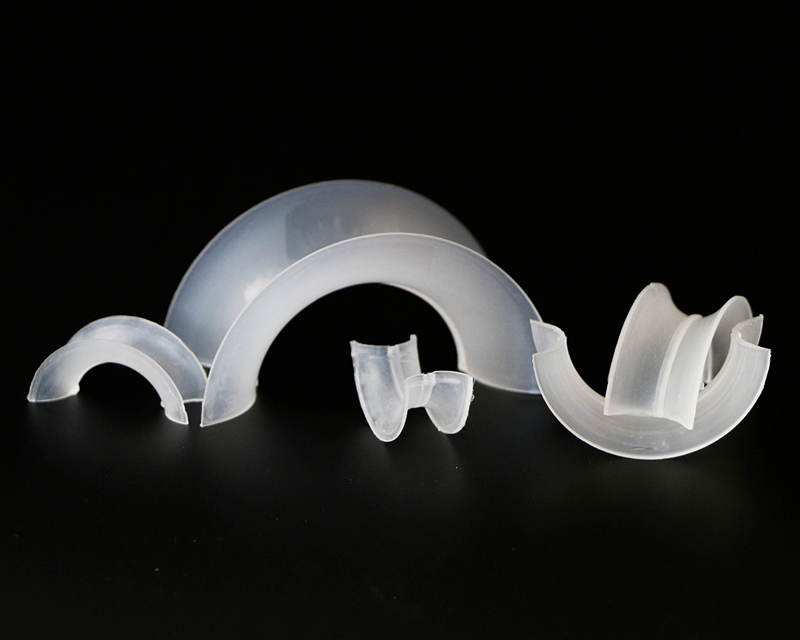

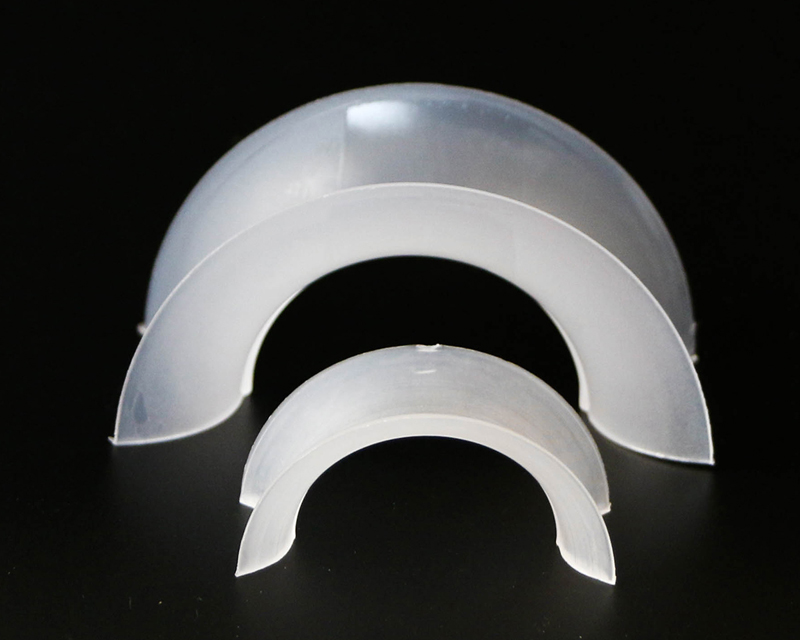

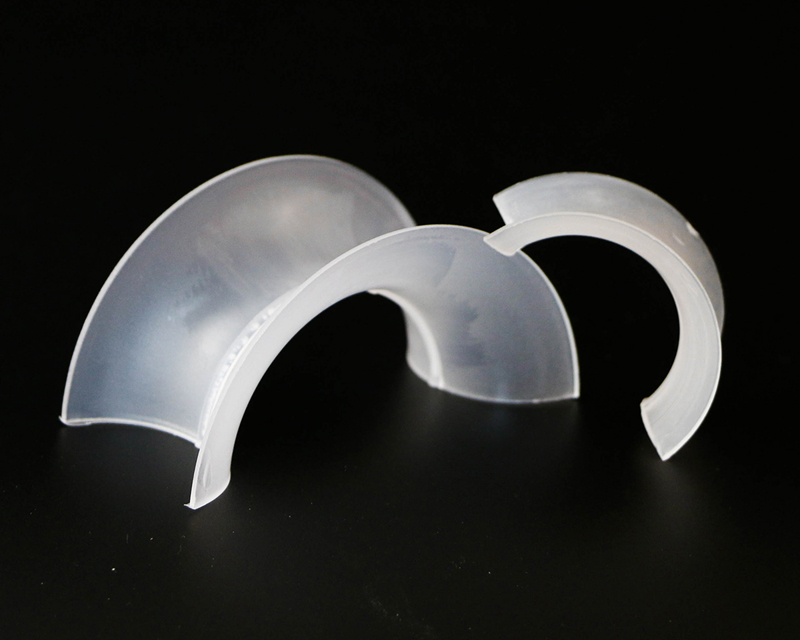

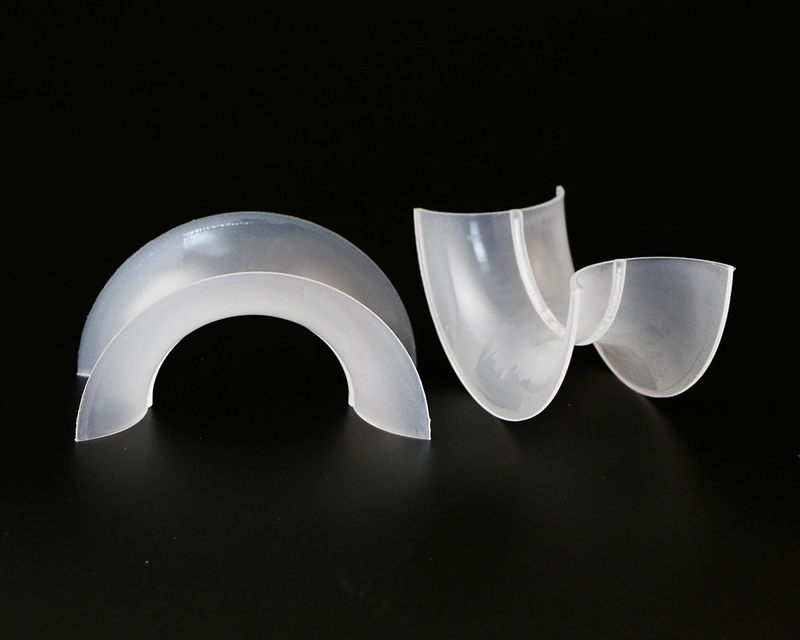

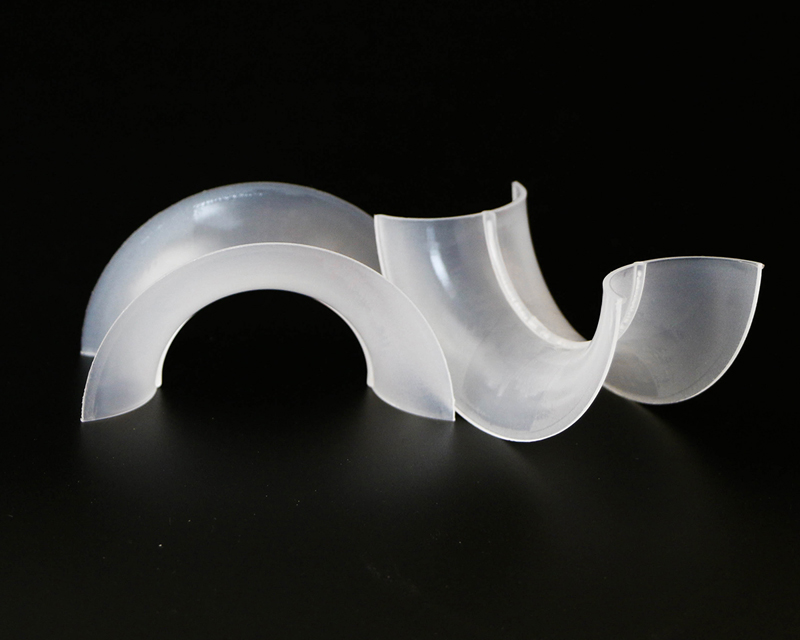

Product overview:

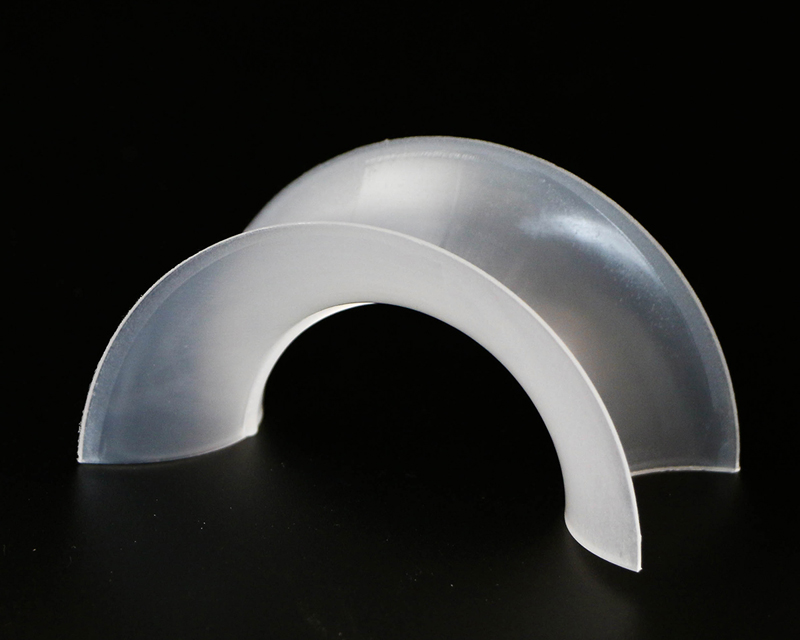

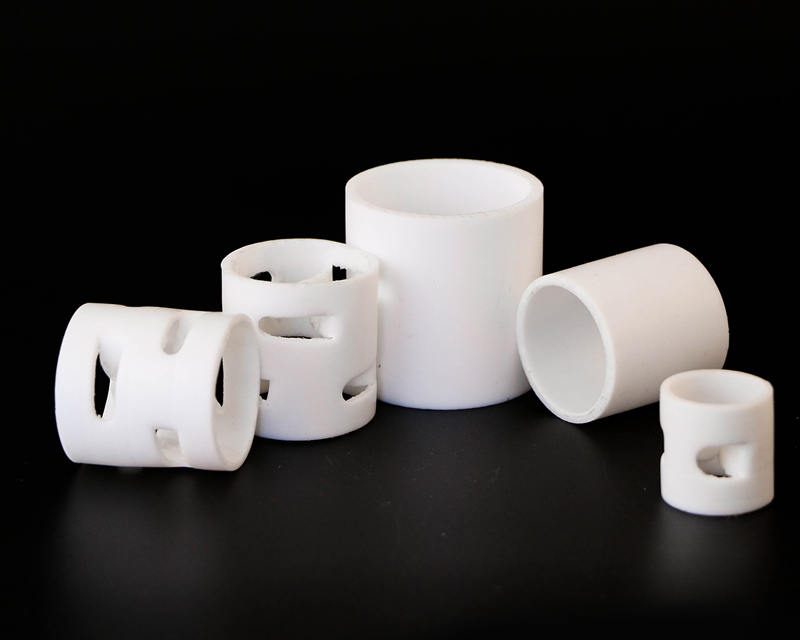

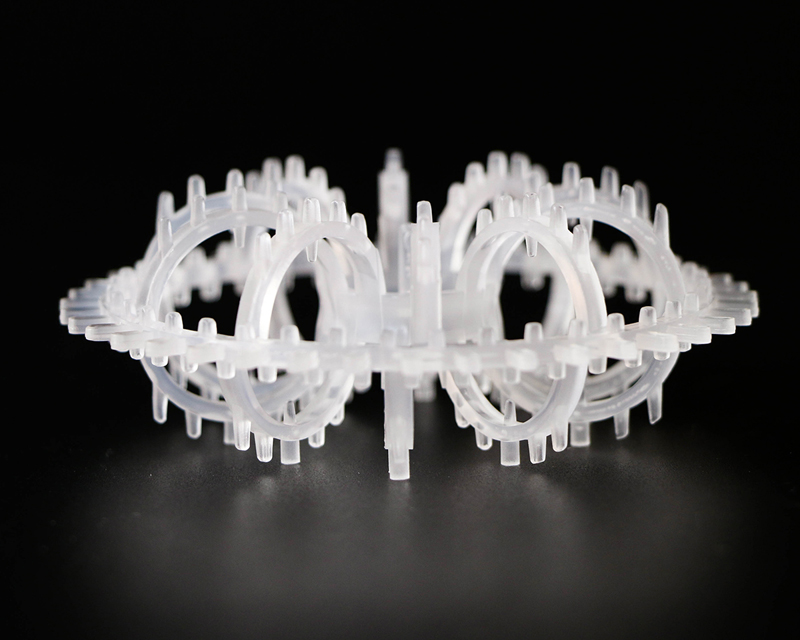

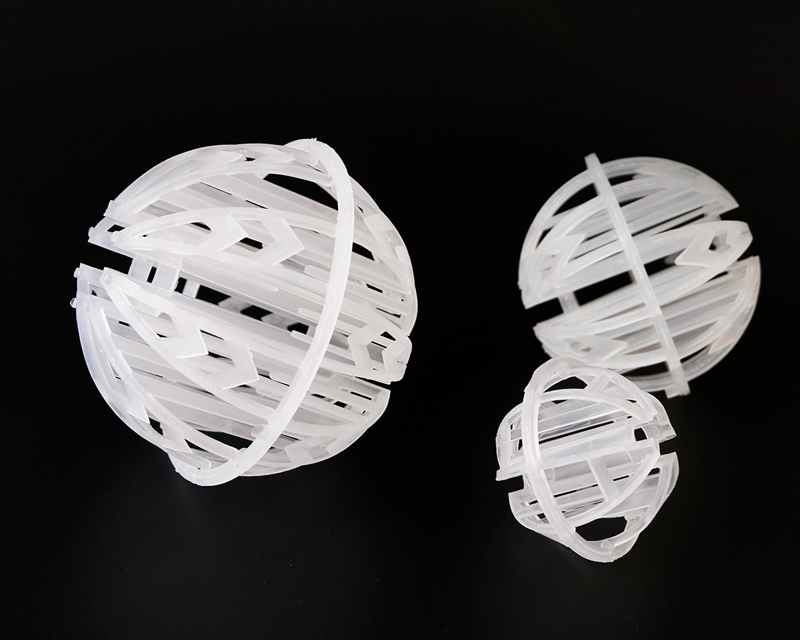

The plastic rectangular saddle ring is made of polyethylene (PE), polypropylene (PP), reinforced polypropylene (RPP), polyvinyl chloride (PVC), chlorinated polyvinyl chloride (CPVC), polyvinylidene fluoride (PVDF), etc. Into the tower packing. It has the characteristics of high porosity, low pressure drop, low mass transfer unit height, high flooding point, sufficient gas-liquid contact, small specific gravity, and high heat and mass transfer efficiency. The operating temperature of these plastic random packing can be 60-280 degrees Celsius. It is widely used in packing towers in petroleum, chemical, chlor-alkali, gas, environmental protection and other industries.

Product Features:

●The plastic rectangular saddle ring has a smooth arc-shaped side in the packing bed, which increases the contact gap between the packings, making it more conducive to the flow and diffusion of gas and liquid in the packing layer, and has the characteristics of reduced pressure and high mass transfer efficiency. .

|

Product name

|

Plastic rectangular saddle ring

|

|

Material

|

PP, PE, PVC, CPVC, PVDF, PTFE

|

|

Service life

|

3 years

|

|

Size mm

|

Specific surface area m2/m3

|

Porosity%

|

Pieces/m3

|

Bulk weight Kg/m3

|

Dry packing factor m-1

|

|

1"

|

25*12.5*1.2

|

288

|

85

|

97680

|

102

|

473

|

|

1-1/2"

|

38*19*1.2

|

265

|

95

|

25200

|

63

|

405

|

|

2"

|

50*25*1.5

|

250

|

96

|

9400

|

75

|

323

|

|

3"

|

76*38*2

|

200

|

97

|

3700

|

60

|

289

|

|

Performance

|

Large porosity, low pressure, low mass transfer unit height, high flooding point, sufficient gas-liquid contact, small specific gravity, high mass transfer efficiency

|

|

Advantages

|

1. The special structure enables large circulation, lower pressure and good mechanical strength.

2. Strong corrosion resistance, large porosity, energy saving and environmental protection, low cost, light specific gravity, easy to load and unload.

|

|

Application field

|

The maximum operating temperature of plastic random packing is 280 degrees Celsius, and it is widely used in packing towers in petroleum, chemical, chlor-alkali, gas, and environmental protection industries.

|

|

Properties/Materials

|

PE

|

PP

|

RPP

|

PVC

|

CPVC

|

PVDF

|

|

Density (after injection)

|

0.98

|

0.96

|

1.2

|

1.7

|

1.8

|

1.8

|

|

Operating temperature

|

90

|

>100

|

>120

|

>60

|

>90

|

>150

|

|

Corrosion resistance

|

GOOD

|

GOOD

|

GOOD

|

GOOD

|

GOOD

|

GOOD

|

|

Compressive strength

|

>6.0

|

>6.0

|

>6.0

|

>6.0

|

>6.0

|

>6.0

|

English

English Chinese

Chinese