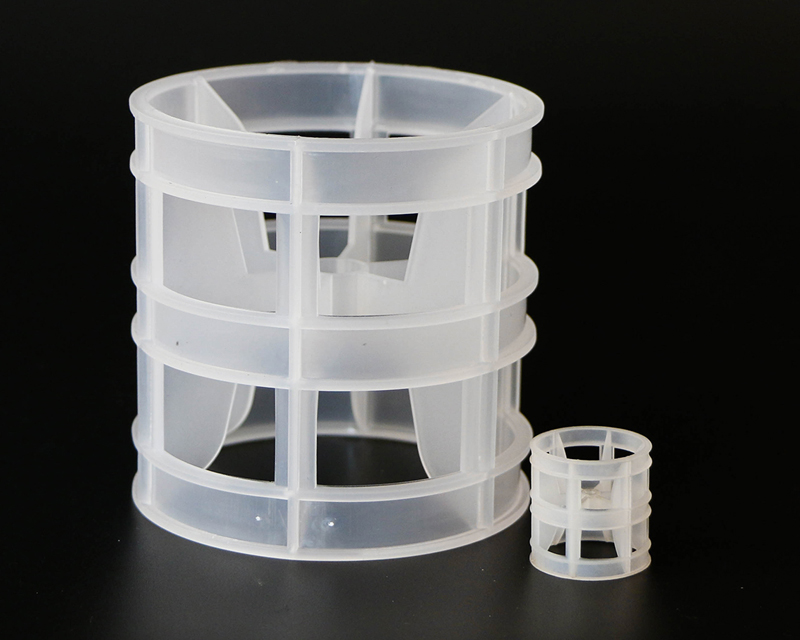

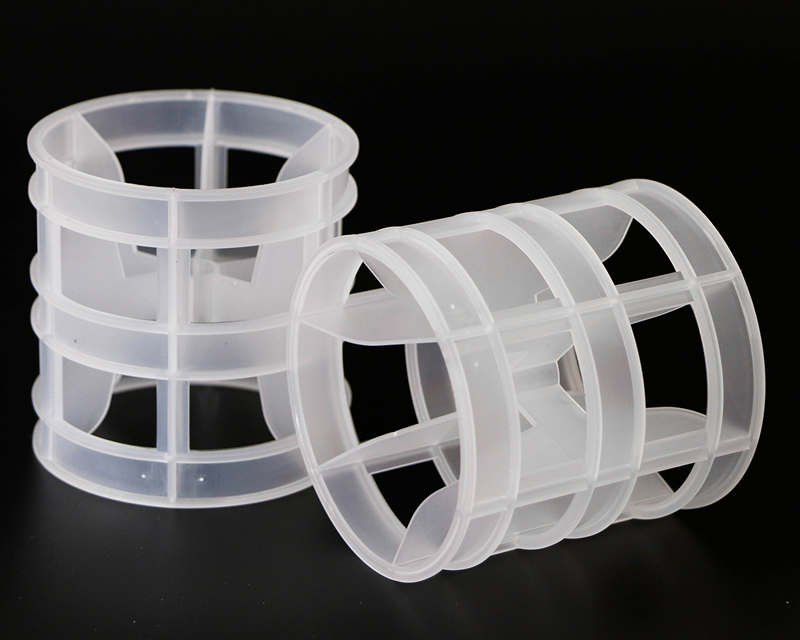

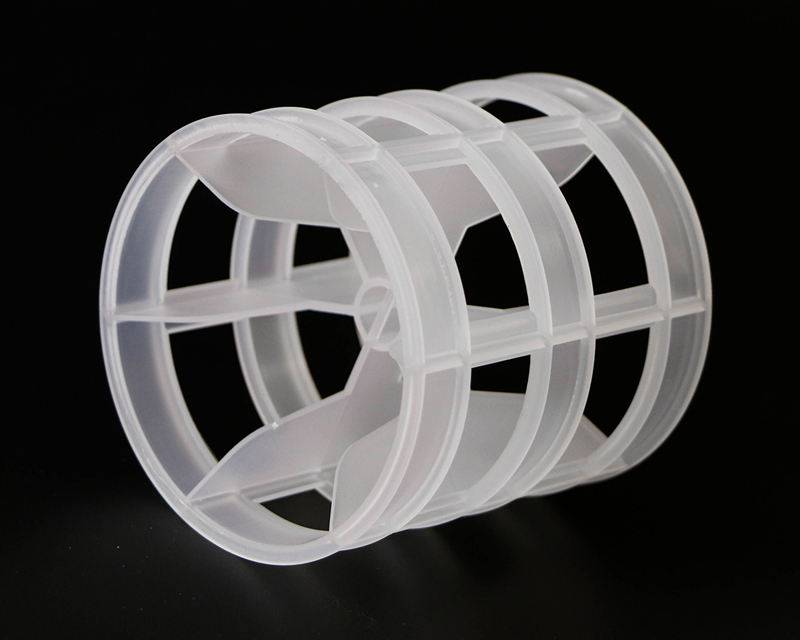

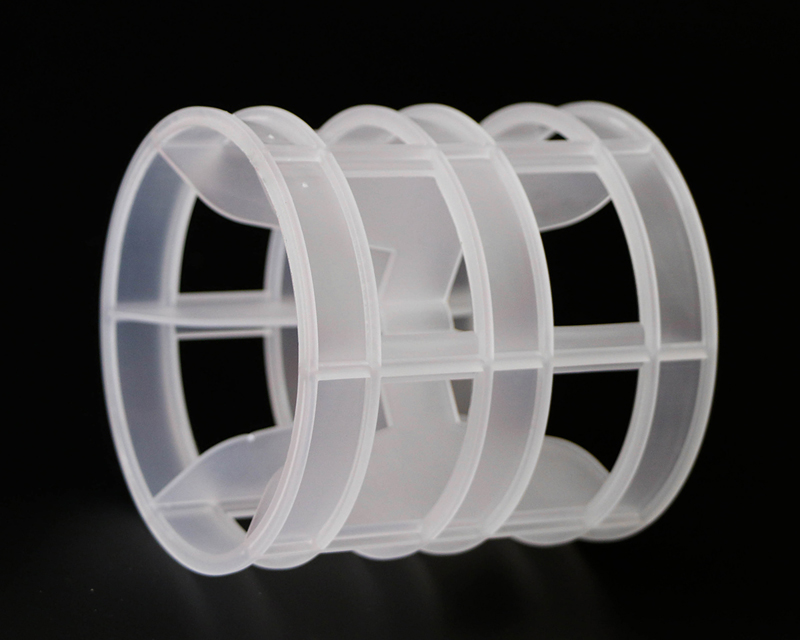

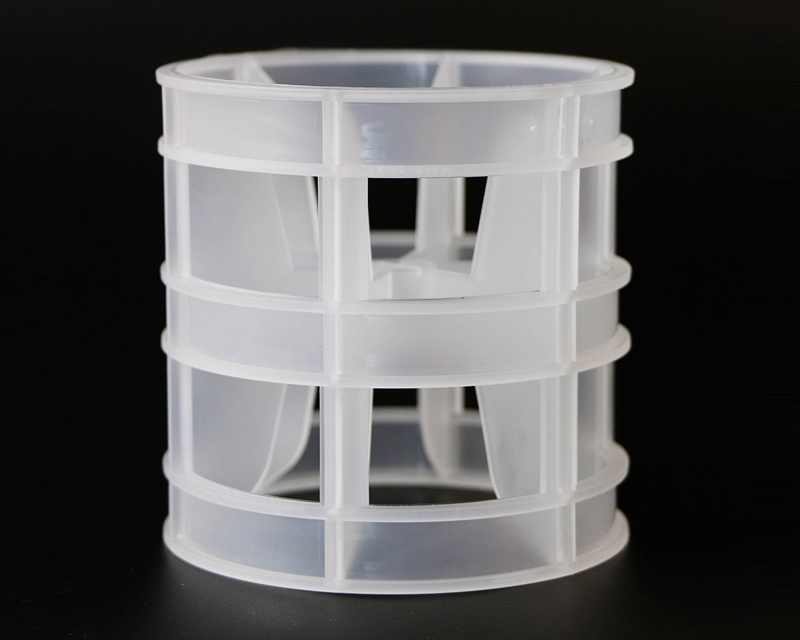

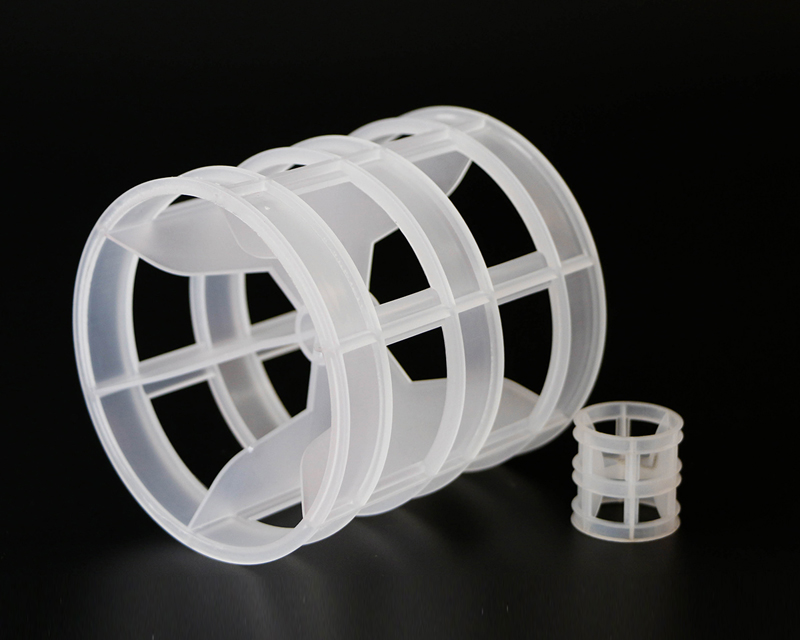

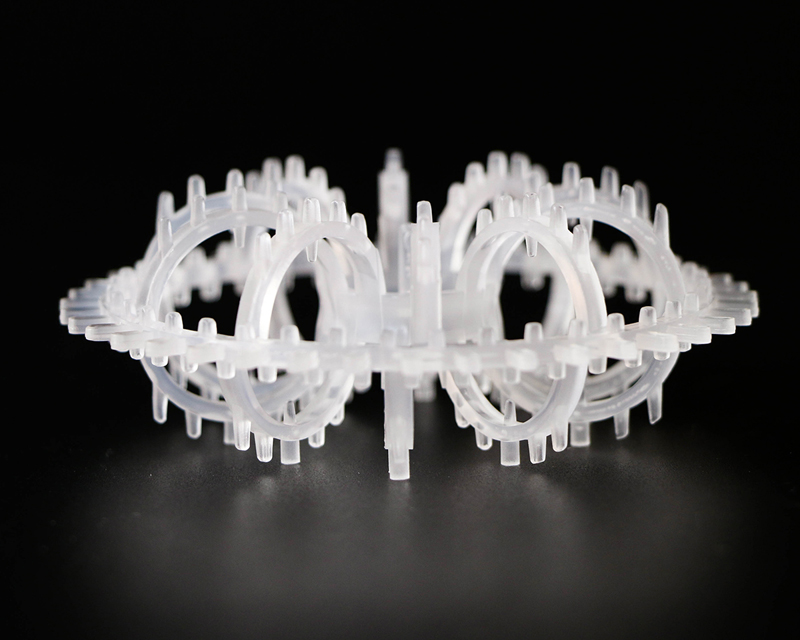

Plastic jet ring packing products are mainly Pall ring packing made by improving mold processing, which is different from the opening method of the ring wall of the Pall ring box. It extends to the ribs in the ring, which makes the window form two open cones in opposite directions. Since the cone guides the liquid flow and air flow to gather and disperse in the ring, it will cause strong interference.

|

Product name

|

Plastic Taylor Garland

|

|

Material

|

PP, PE, PVC, CPVC, RPP, PVDF AND ETFE PTFE

|

|

Service life

|

3 years

|

|

Size mm

|

Specific surface area m2/m3

|

Porosity%

|

Pieces/m3

|

Bulk weight Kg/m3

|

Dry packing factor m-1

|

|

25*9*(1.5*2) (5 ring)

|

269

|

82

|

170000

|

85

|

488

|

|

47*19*(3*3) (9 ring)

|

185

|

88

|

32500

|

58

|

271

|

|

51*19*(3*3) (9 ring)

|

180

|

89

|

25000

|

57

|

255

|

|

59*19*(3*3) (12 ring)

|

127

|

89

|

17500

|

48

|

213

|

|

73*27.5*(3*4) (12 ring)

|

94

|

90

|

8000

|

50

|

180

|

|

95*37*(3*6) (18 ring)

|

98

|

92

|

3900

|

52

|

129

|

|

145*37(3*6) (20 ring)

|

65

|

95

|

1100

|

46

|

76

|

|

Performance

|

Large porosity, low pressure, low mass transfer unit height, high flooding point, sufficient gas-liquid contact, small specific gravity, high mass transfer efficiency

|

|

Advantages

|

1. The special structure enables large circulation, lower pressure and good mechanical strength.

2. Strong corrosion resistance, large porosity, energy saving and environmental protection, low cost, light specific gravity, easy to load and unload.

|

|

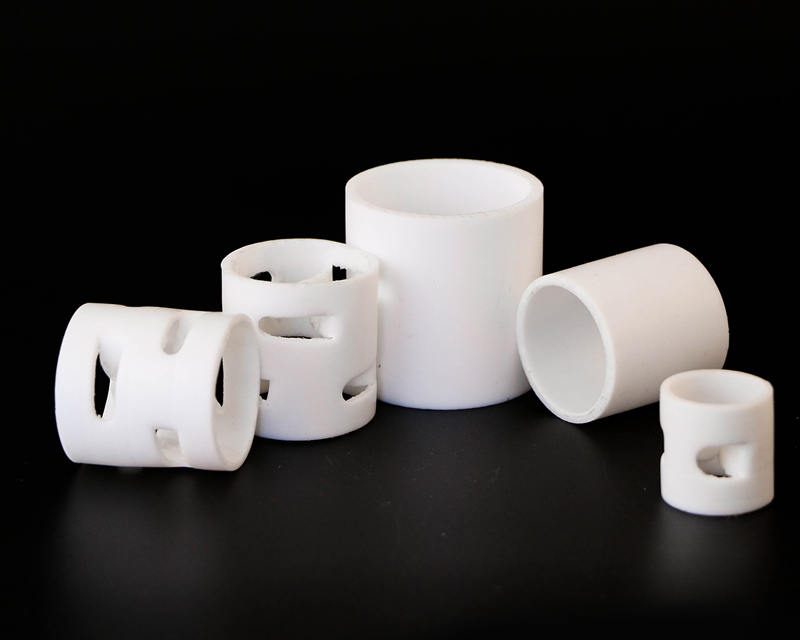

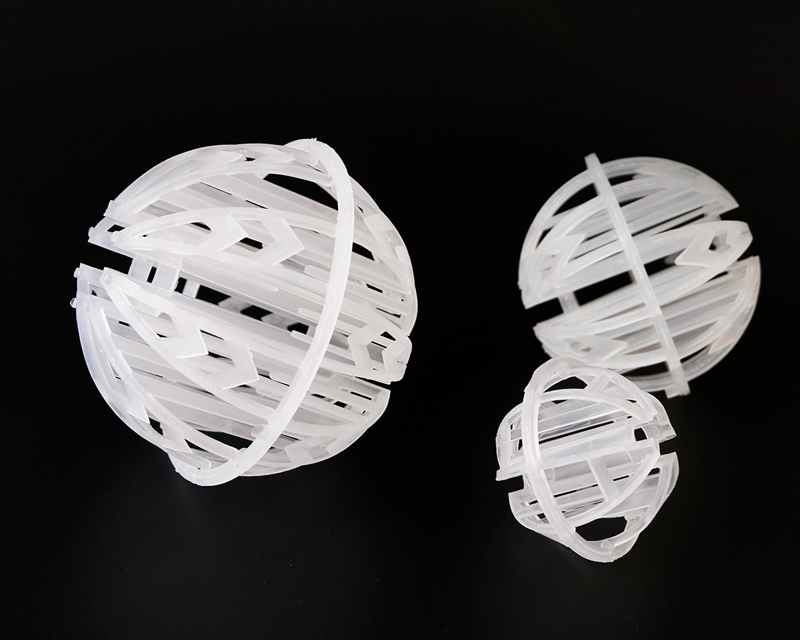

Application field

|

Used in gas absorption tower, acid gas adsorption system, fertilizer production. The maximum operating temperature of plastic random packing is 280 degrees Celsius, and it is widely used in packing towers in petroleum, chemical, chlor-alkali, gas, and environmental protection industries.

|

|

Model

|

Specific surface area m2/m3

|

Porosity%

|

Number of piles per/m3

|

Packing factor m-1

|

|

65

|

86

|

0.92

|

2900

|

44

|

|

75

|

72.3

|

0.90

|

1900

|

38

|

|

90

|

68

|

0.89

|

1200

|

37

|

English

English Chinese

Chinese