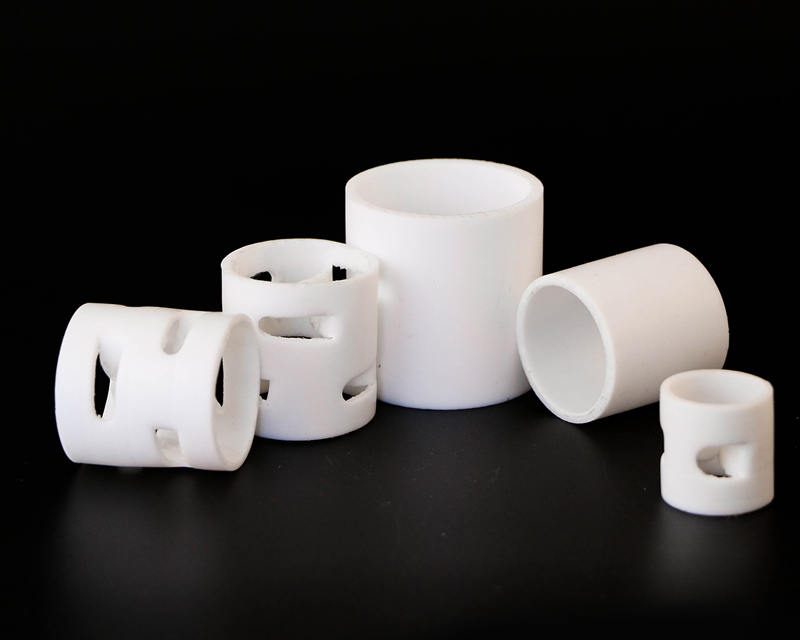

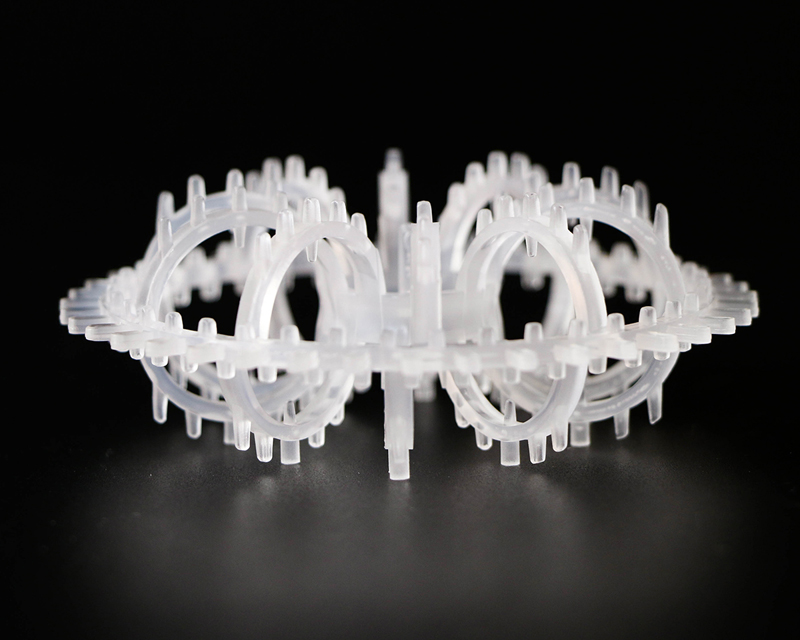

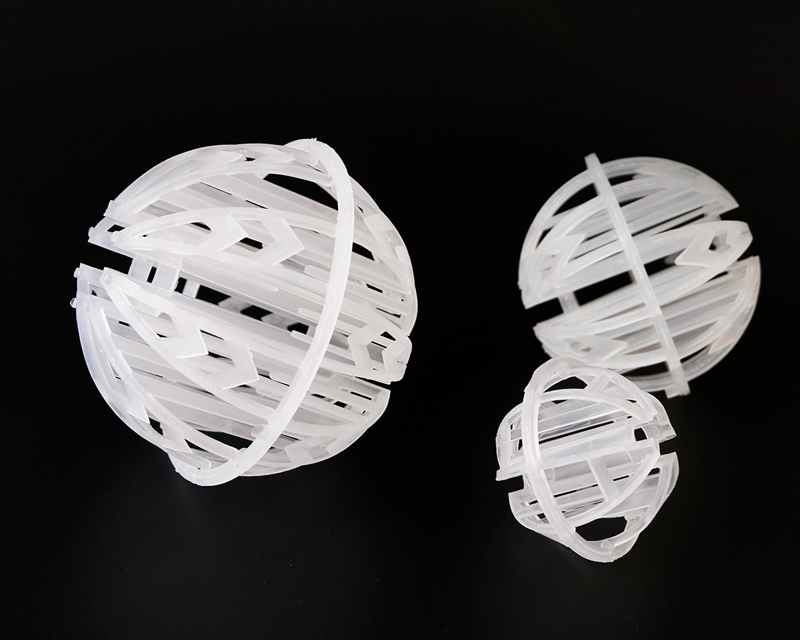

Product overview:

In the 1970s, Noton Company of the United States made improvements to the ordinary rectangular saddle ring packing, changing the fan-shaped arc surface into a zigzag shape, and adding openings on the saddle back, so that the passage in the packing layer is more smooth and the liquid distribution is improved. Performance, reduces the resistance of the gas to pass, and improves the mass transfer performance. Different saddle ring plastic saddle packing is similar to the shape of a saddle. This packing layer is mainly composed of arc-shaped liquid channels, and the voids in the packing layer are more continuous than annular packing (especially than Raschig ring packing).

Product Features:

●Plastic saddle ring packing has large porosity, low pressure drop and mass transfer unit height, high flooding point, sufficient vapor-liquid contact, small specific gravity, high mass transfer efficiency, pressure drop, large flux, high efficiency, and load flexibility Large, good stain resistance and other characteristics. It is widely used in packed towers in petroleum, chemical, chlor-alkali, gas, environmental protection and other industries, such as dewaxing oil refining extraction, demethanization, phthalic anhydride refining, etc.

●The plastic saddle ring is an improvement of the rectangular saddle ring. Its characteristic is to improve the fan-shaped arc surface into a shell-shaped arc surface with serrated edge, and increase the opening to make the inner and outer surfaces of the filler communicate, increase the free passage of the fluid, which is conducive to the liquid distribution and surface renewal, so it is more rectangular than the saddle ring treatment. High capacity, small pressure drop and improved mass transfer performance. Generally made of ceramics and plastics.

|

Product name

|

Plastic saddle ring

|

|

Material

|

PP/RPP/PVC/CPVC/PVDF,PTFE

|

|

Service life

|

3 years

|

|

Size mm

|

Specific surface area m2/m3

|

Porosity%

|

Pieces/m3

|

Bulk weight Kg/m3

|

Dry packing factor m-1

|

|

25*12.5*1.2

|

260

|

90

|

51200

|

92

|

390

|

|

38*19*1.2

|

178

|

96

|

25200

|

75

|

201

|

|

50*25*1.5

|

168

|

97

|

6300

|

76

|

184

|

|

76*38*2.6

|

130

|

98

|

3700

|

64

|

138

|

|

Performance

|

Large porosity, low pressure, low mass transfer unit height, high flooding point, sufficient gas-liquid contact, small specific gravity, high mass transfer efficiency

|

|

Advantages

|

1. The special structure enables large circulation, lower pressure and good mechanical strength.

2. Strong corrosion resistance, large porosity, energy saving and environmental protection, low cost, light specific gravity, easy to load and unload.

|

|

Application field

|

The maximum operating temperature of plastic random packing is 280 degrees Celsius, and it is widely used in packing towers in petroleum, chemical, chlor-alkali, gas, and environmental protection industries.

|

|

Properties/Materials

|

PE

|

PP

|

RPP

|

PVC

|

CPVC

|

PVDF

|

|

Density (after injection)

|

0.98

|

0.96

|

1.2

|

1.7

|

1.8

|

1.8

|

|

Operating temperature

|

90

|

>100

|

>120

|

>60

|

>90

|

>150

|

|

Corrosion resistance

|

GOOD

|

GOOD

|

GOOD

|

GOOD

|

GOOD

|

GOOD

|

|

Compressive strength

|

>6.0

|

>6.0

|

>6.0

|

>6.0

|

>6.0

|

>6.0

|

English

English Chinese

Chinese